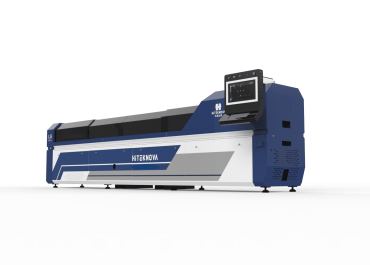

The HITEKNOVA MF1600 / MF1600T Series is a smart, high-precision, and highly flexible roll-forming system designed for a wide range of light-steel construction applications.

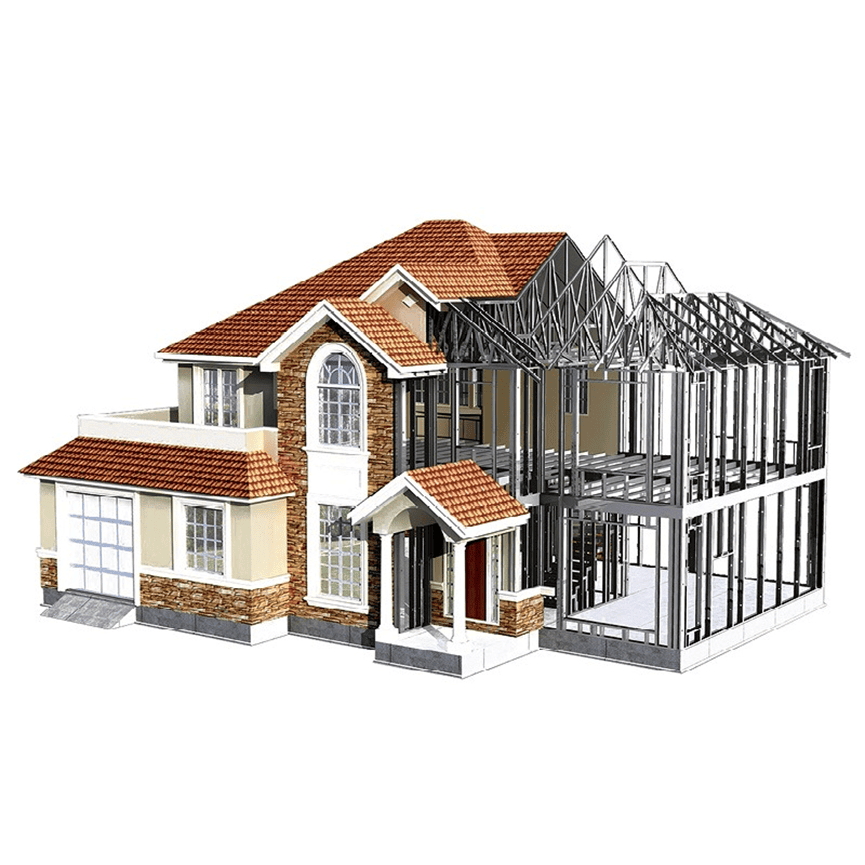

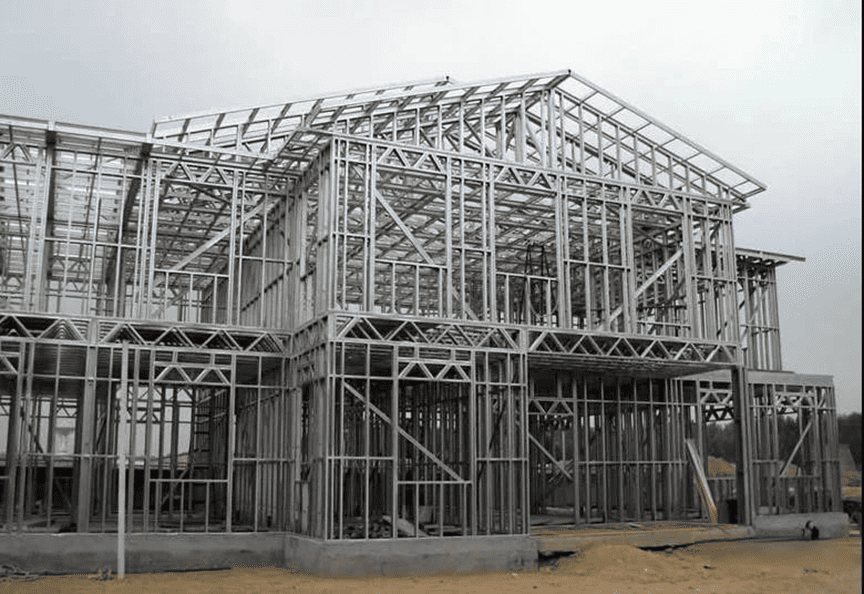

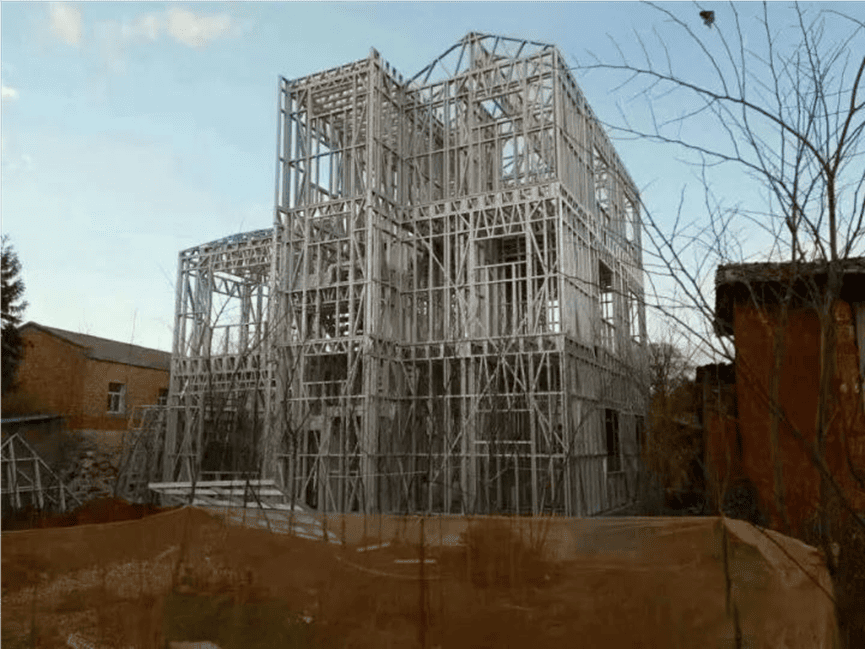

It is ideally suited for 1–3 level residential houses and villas, as well as 1–6 level apartment buildings, and is fully compatible with both CC and CU framing systems. Engineered for exceptional forming accuracy, wide profile adaptability, and enhanced production efficiency, the MF1600 Series delivers reliable performance for both residential and light commercial construction.

Producing profiles from 75mm to 160mm in width, and material thicknesses up to 1.6mm, the MF1600/MF1600T achieves forming speeds of up to 35m/min, ensuring efficient output across various building applications.

The MF1600 / MF1600T supports a wide range of structural components, including:

- Roof trusses in 75mm, 89mm, and 140mm

- Light-duty floor joists in 89mm, 140mm, and 160mm

- Commercial wall studs in 75mm, 89mm, 100mm, 140mm, and 160mm

With its high adaptability and precision engineering, the MF1600 / MF1600T is an excellent choice for modular construction, multi-story residential projects, and high-strength framing requirements.

| Quick detail | |

| Item | Specification |

| Model number | MF1600 |

| Dimensions L x W x H | 5.8m x 1.55m x 1.95m |

| Weight | 11T |

| Drive Motor Power | 14KW |

| Hydraulic Power | 11KW |

| Hydraulic Tank | 200L |

| Forming Stages | 17 |

| Line Speed | 35m/min |

| Profile Width Range | 75-160mm |

| Thickness | 0.75-1.6mm |

| Touch Screen | Panel PC (Windows 10) |

| Machine Input Files | CSV |

| Tooling | 10 Standard Tools |

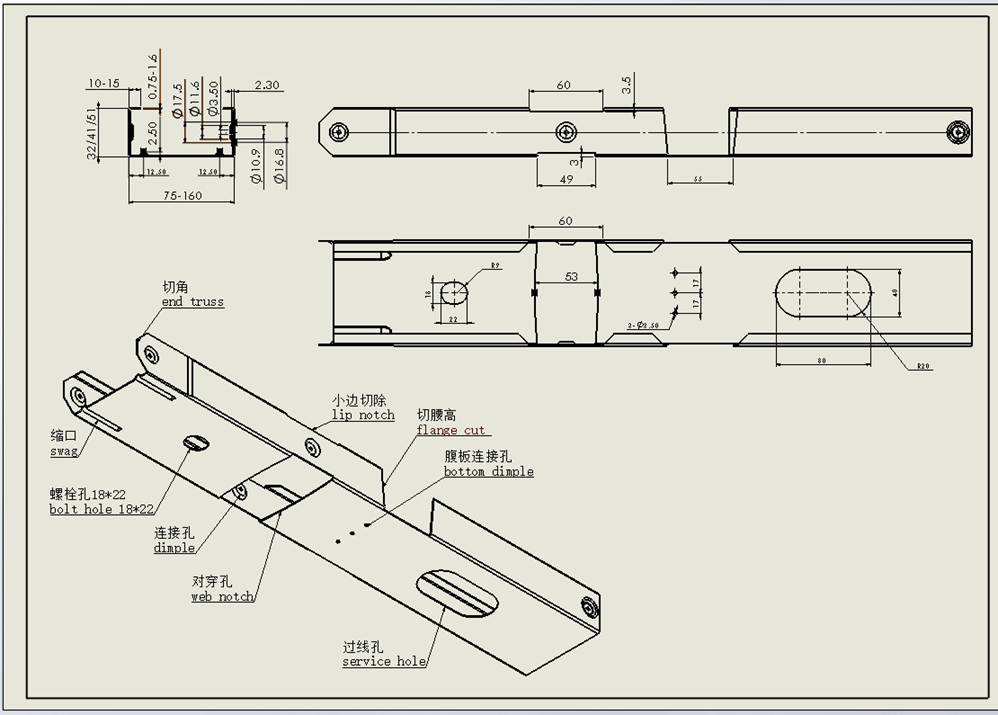

| 1、End truss;

2、Flange cut left; 3、Flange cut right; 4、Dimple; 5、Bottom dimple; 6、Bolt hole 18*22; 7、Service hole; 8、Web notch; 9、Swag; 10、End Cut-off |

|

| Component Marking | Dual Head Inkjet Printer |

Profile Drawing

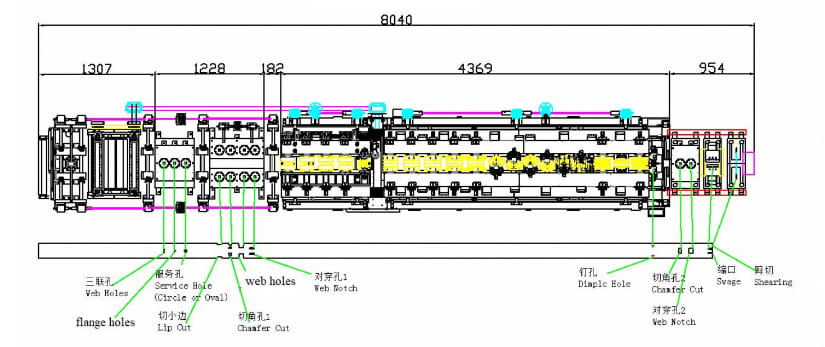

Machine Components

•Hydraulic de-coiler ———————————————————— 1 set

•Leveling Device ————————————————————— 1 set

•Lip and flange cut out device————————————————–1 set

•Roll Forming System———————————————————- 1set

•Punching Device ————————————————————– 1 set

•Cutting Device——————————————————————–1 set

•PLC Control System———————————————————– 1 set

•Out-let Table——————————————————————— 1 set

Flow Chart

The flow chart is showing below.

De-coiler→ Leveling Device→ Punching Device→ Roll Forming System → Cutting

Device →Out-let table

DAHEZB Machine Pictures

Application