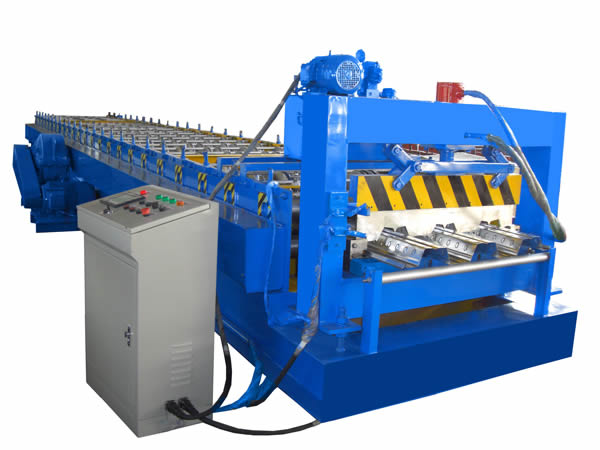

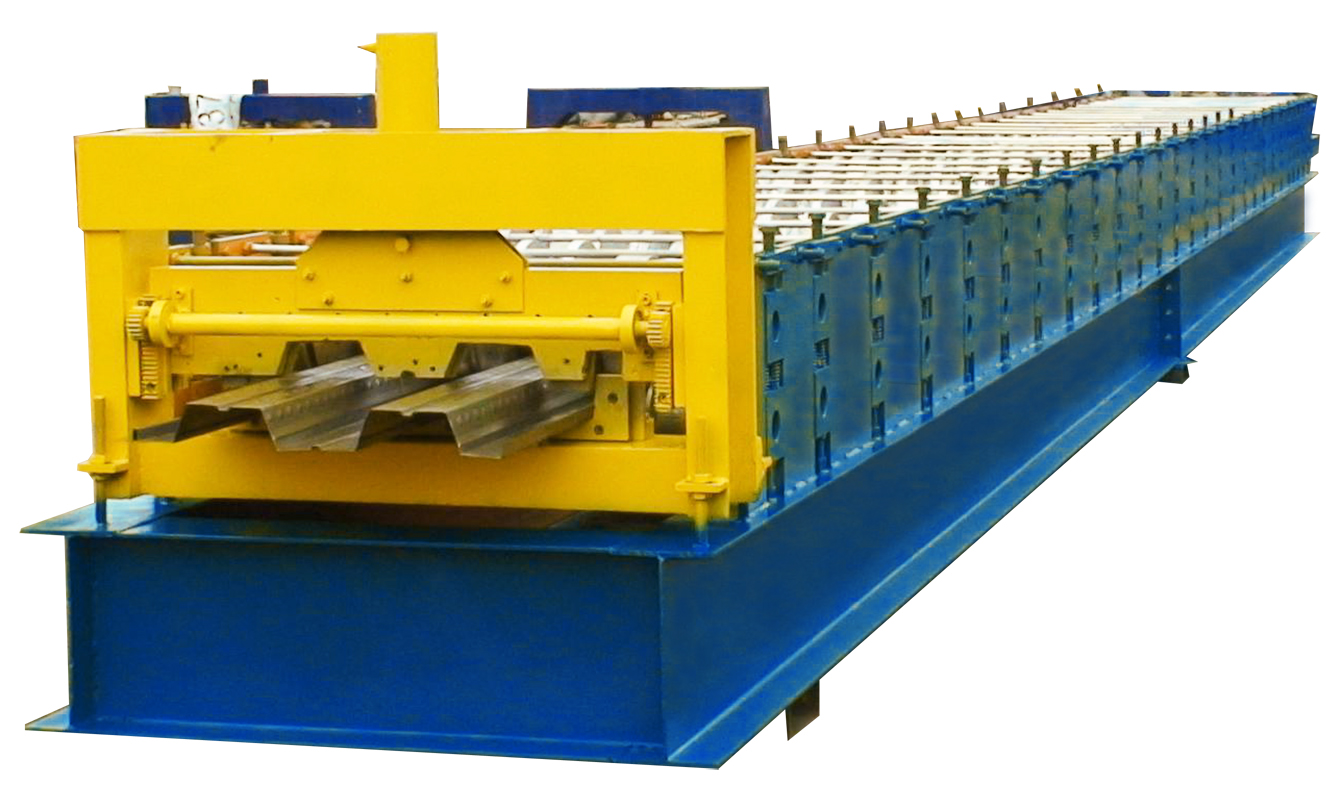

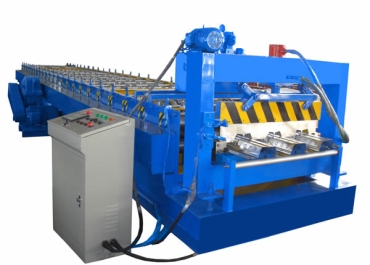

decking forming machine consists of uncoiler and its base, coil sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, controlling system, supporter table. The corrugated profile sheet produced by this machine has high strength with big rib, which adheres well to concrete. It’s best to be used as the floor of high buildings, and the cost of such floor is low.

Features

High solid forming stand guarantees the stable forming and uniform high quality of final products.

Able to secure higher productivity since the management of the line is automated by controlling an electronic system.

Improved cutting method minimizes the tolerandce of cutting length.

Technical Parameters

| No | Item | Parameter | Remark | |

| 1 | Suitable

Material | Type | Galvanzied steel | |

| Width(mm) | 1250 | According to customer’s requirement | ||

| Thickness(mm) | 0.8-1.2 | According to customer’s requirement | ||

| Yield Strength(Mpa) | 230-300 | According to customer’s requirement | ||

| 2 | Forming Speed(m/min) | 20 | Not including cutting time | |

| 3 | Roller Material | No.45 steel | with hard chromized | |

| 4 | Cutting Model | Hydraulic Cutting | According to customer’s requirement | |

| 5 | Power source | Type | 380V/3PH/50HZ | According to customer’s requirement |

Machine Components

| No | Name | Quantity | Remarks | |

| 1 | Decoiler | 1set | Up to customer | |

| 2 | Main machine | Pre-cutting device | 1set | Up to customer |

| Feeding device | 1set | |||

| Roll forming system | 1set | |||

| Post cutting device | 1set | |||

| Hydraulic system | 1set | |||

| 3 | Electric control system | 1set | ||

| 4 | Supporter/Automatic Stacker | 1set | ||