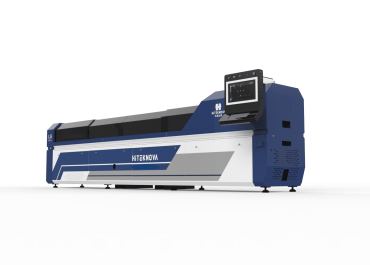

ONE MF2000=THREE OR ABOVE THREE SINGLE TYPE MACHINES

Hiteknova MF2000 (multi-function) can meet the various demands of light gauge steel framing. It suits for all popular lgsf CC & CU system, range to 89-200mm (3.5-7.87 inch) , the thickness can even up to 0.75-1.6mm (0.029-0.062 inch).

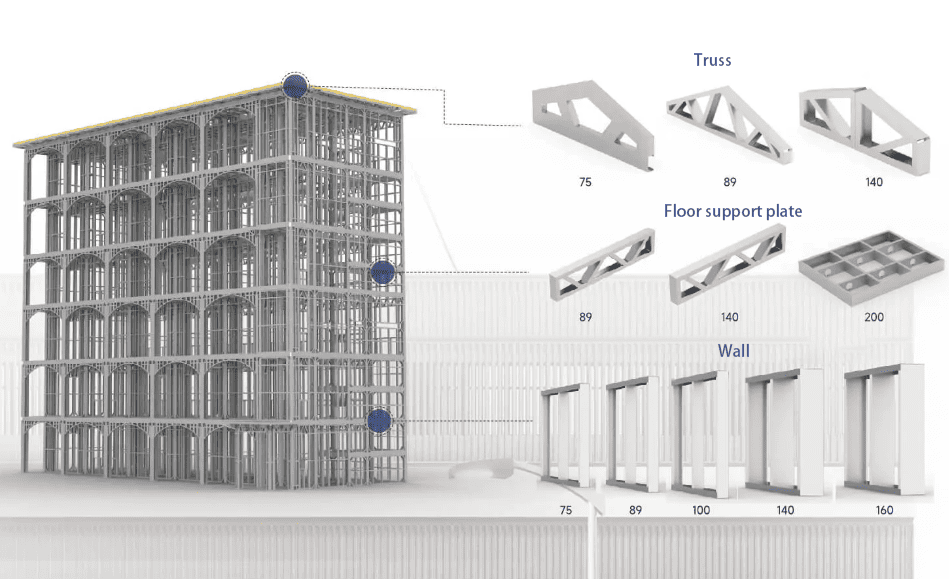

MF2000 is designed specifically for the wall panels, roof and floor trusses as well as other building framings. It can fit for the different building styles: villas, low-rise buildings, and high-rise apartments. All our operations are for the automatic design with some manual jobs, easily for the opearation, all our design are including the different punching dies, can compatible with the world’s popular construction design software.

Multi Profile

CC/CU:

“U” Profile Dimensions

Profile Height (flange):41mm(1.61 inch)

Profile Width (web): 75-200 mm(2.95-7.87 inch)

“C” Profile Dimensions

Profile Height (flange): 41mm(1.61 inch)

Profile Width (web): 75-200 mm(2.95-7.87inch)

Profile Lip (flange): (8~15)mm(0.31-0.59 inch)

Material Thickness: 0.75-1.6 mm(0.029-0.062 inch),Q235、Q345、G550, hot-rolled galvanized steel strip

Technology Parameters

| Description | |

| Machine Weight | 10T |

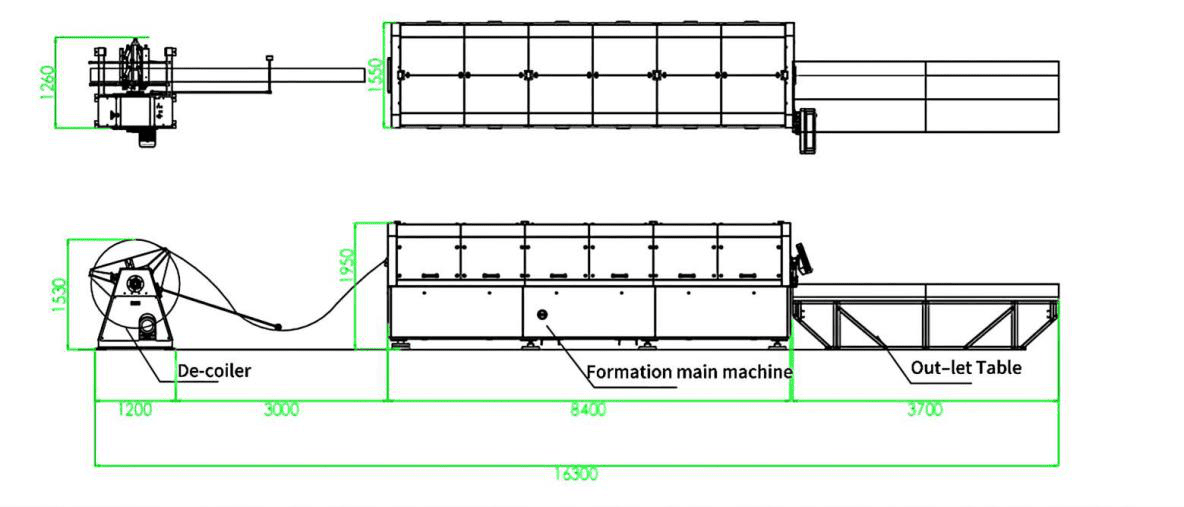

| Forming Parts Dimension | 8.5m x 1.55m x 1.95m(L*W *H) |

| De-coiler | Manual automatic de-coiler |

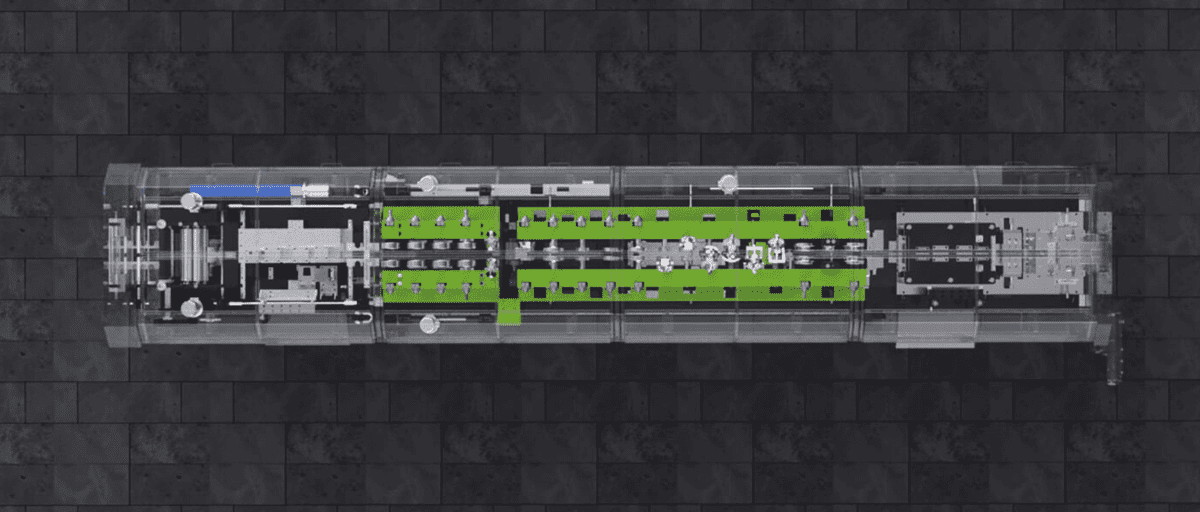

| Feeding and Leveling Device | 2 groups for upper and 3 groups for down |

| Hole Punching | Hydraulic punching |

| Hole Punching Accuracy | ± 1 mm |

| Hole Type | End truss, Swage, Web hole, Dimple, Web notch, Service hole, Web hole , Flange cut , Lip cut |

| Roll Forming System | High speed 35m/min, (the actual production speed depends on the number of punched holes) |

| Hydraulic Cutting Material | Cr12、Cr12MoV |

| Hydraulic Pressure | 16Mpa |

| Online Printer | Marks and Item Number |

| Out-let Table | 4 meters |

| Safety Guard | Each parts of safety guard is linked with lock |

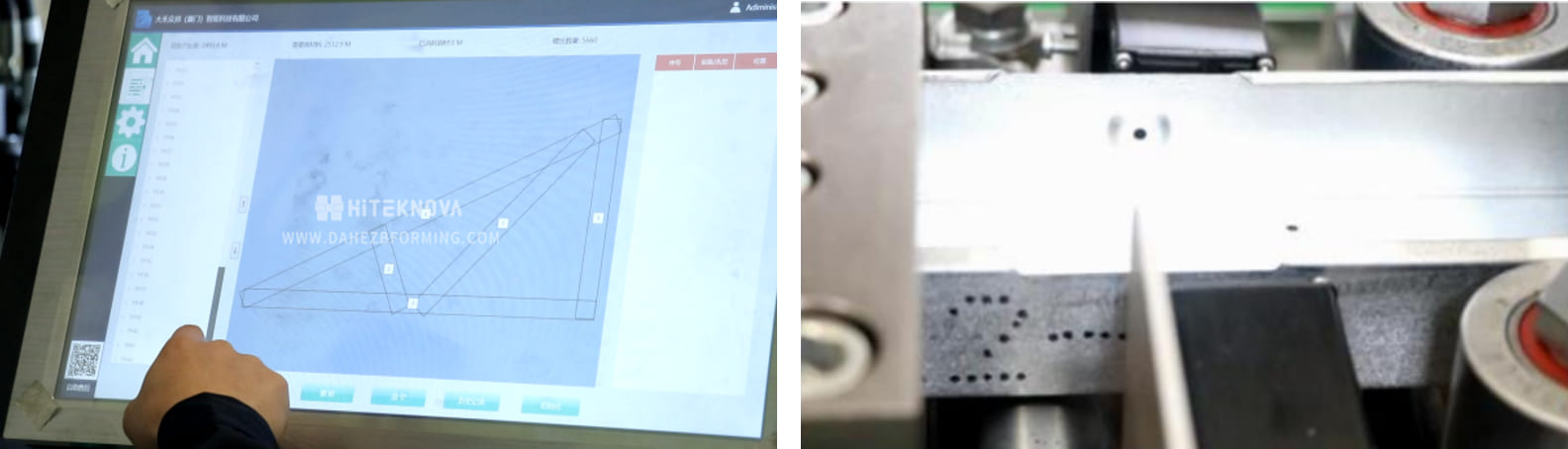

| Computer System | Dahe’s CSV |

| Main Control Cabinet | 2 electrical main control cabinets |

| Touch Screen | 21-inch |

| Controlling Software | LG-R1 |

| External Controller | Wireless remote |

| Voltage Power | 380V 3-phase 50HZ |

| Drive Motor Power | Servo motor 14KW |

| Fuel Tank | 200L |

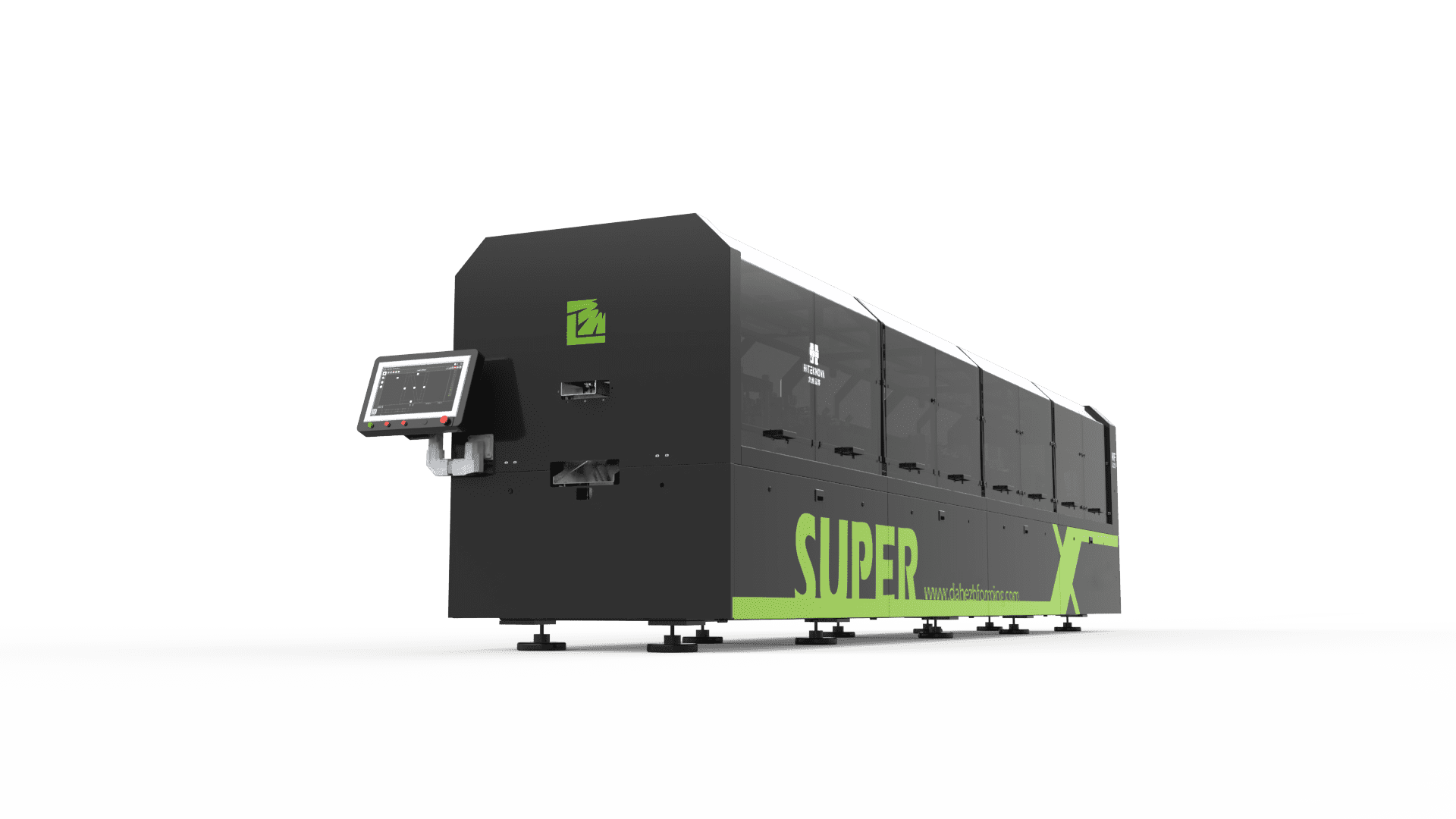

| Machine Colors | Black |

| Free Spare Parts | Other easy wear parts |

Flow chart

De-coiler→ Leveling Device→ Punching Device→ Roll Forming System → Punching Device and Cutting Device →Out-let table

The weight of the Machine: About 10T

The dimension of forming parts: (length) 8.5m x (width) 1.55m x (height) 1.95m (334.64*64.02*76.77 inch).

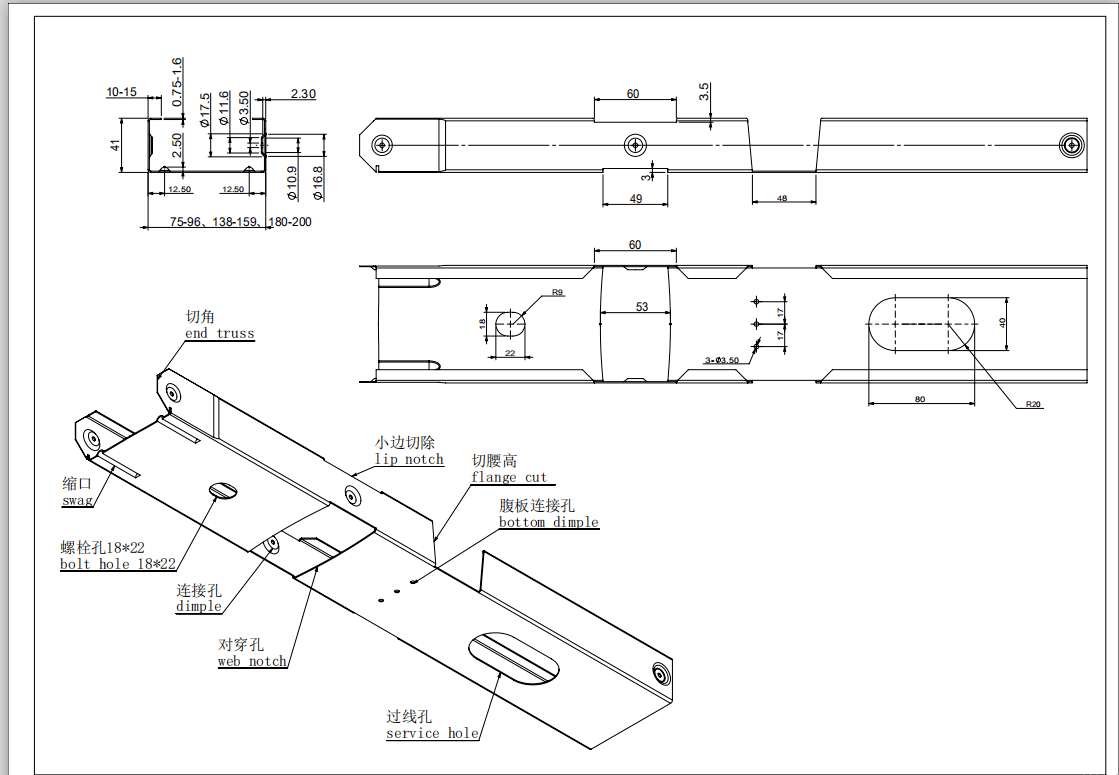

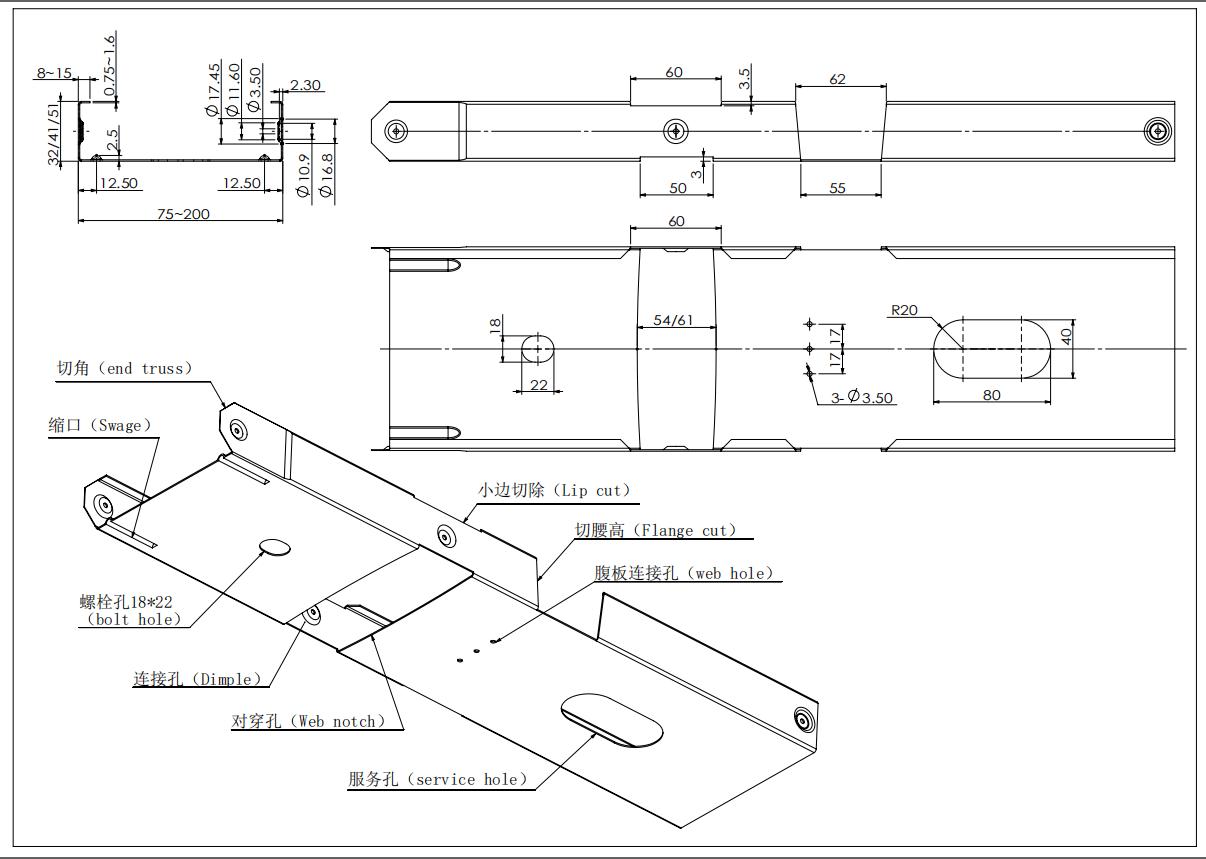

Profile Drawings

| Standard Metric Sizes | |

| Web Width | 75-96mm, 138-159mm, 180-200mm |

| Flange Height | 41mm |

| Lip Width | 8-15mm |

| Lip Cut | 60mm |

| Flange Cut | 41mm |

| Bottom Dimple | 3-Φ3.50mm |

| Service Hole | 80*40mm |

| Web Hole | 18*22mm |

| Dimple Hole | 10.9* 16.8mm |

| Max Material Thickness | 0.75-1.6 mm |

| Standard Imperial Sizes | |

| Web Width | 2.95″-7.87″ |

| Flange Height | 1.61″ |

| Lip Width | 0.31″-0.59″ |

| Lip Cut | 2.36″ |

| Flange Cut | 1.61″ |

| Bottom Dimple | 0.11″-Φ0.13″ |

| Service Hole | 3.14″*1.57″ |

| Web Hole | 0.7″*0.86″ |

| Dimple Hole | 0.42″*0.66″ |

| Max Material Thickness | 0.029″-0.062″ |

- Custom Service Holes and Slots available on request

- Custom Bolt Hole sizes available on request

- Custom Web Holes available on request

- Custom Lip cut and Flange cut available on request

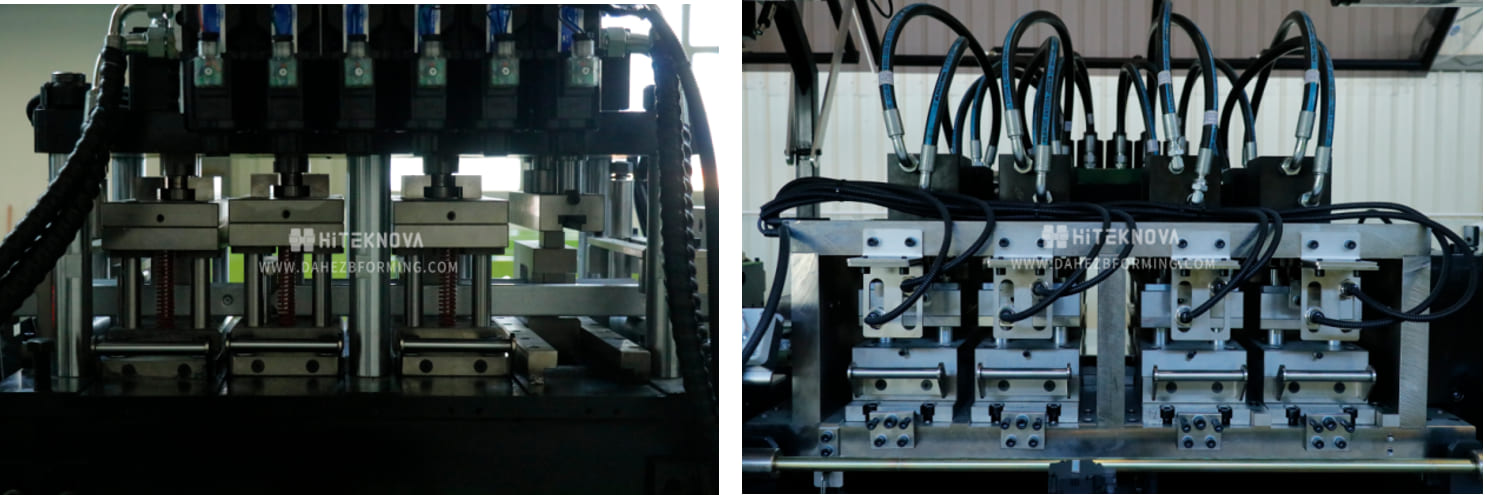

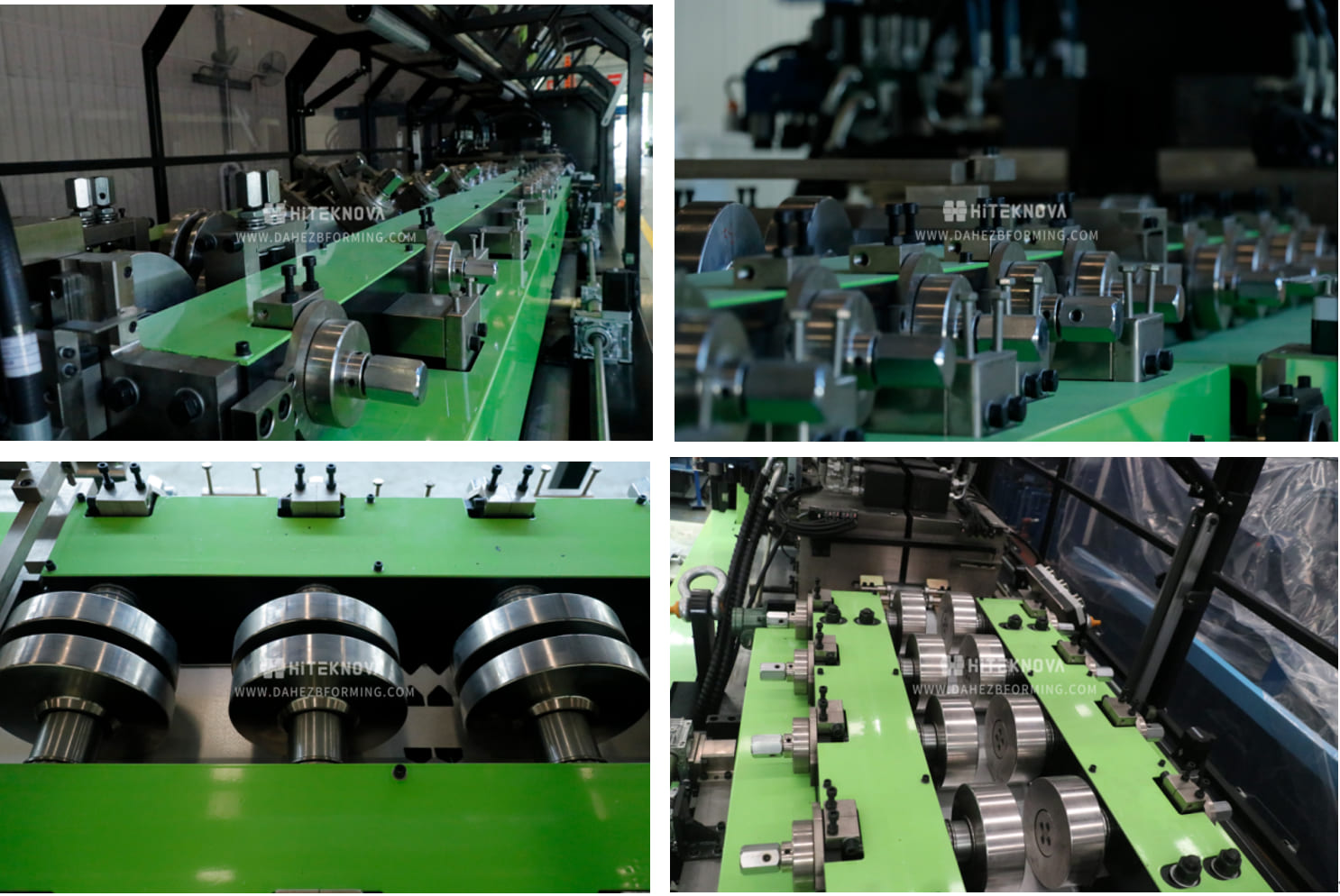

Machine Detail

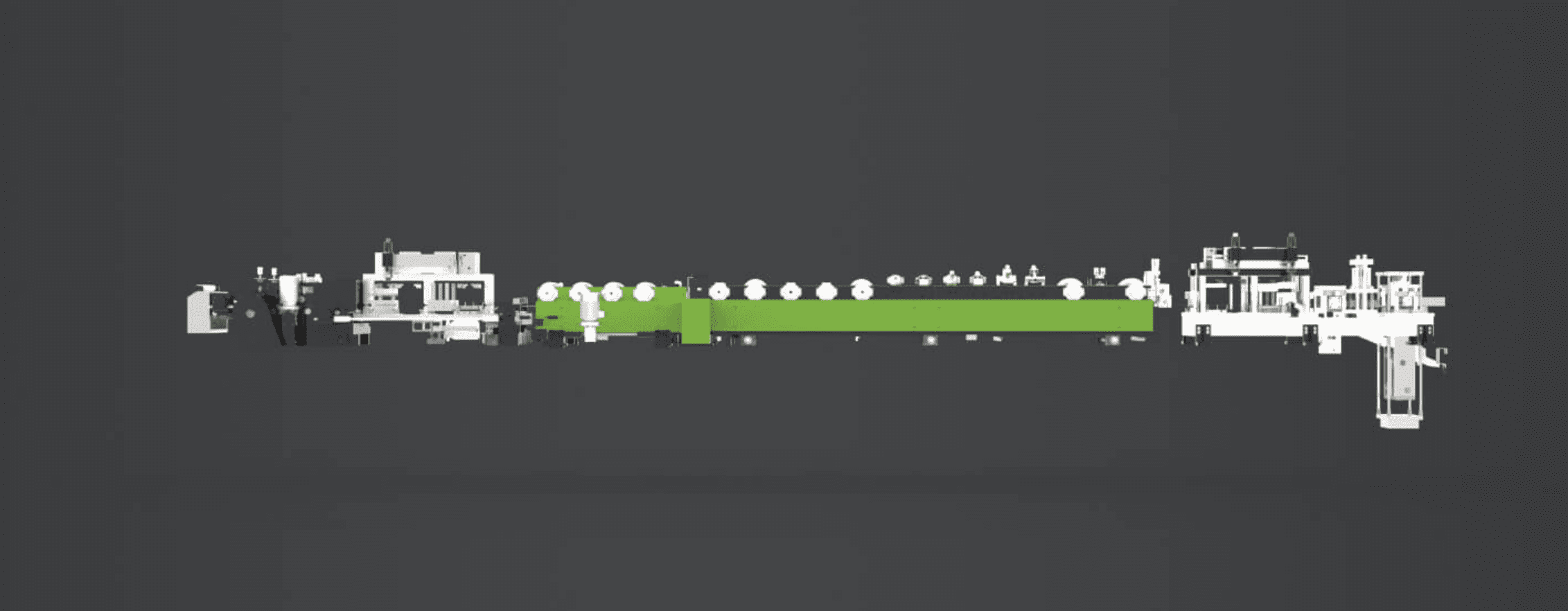

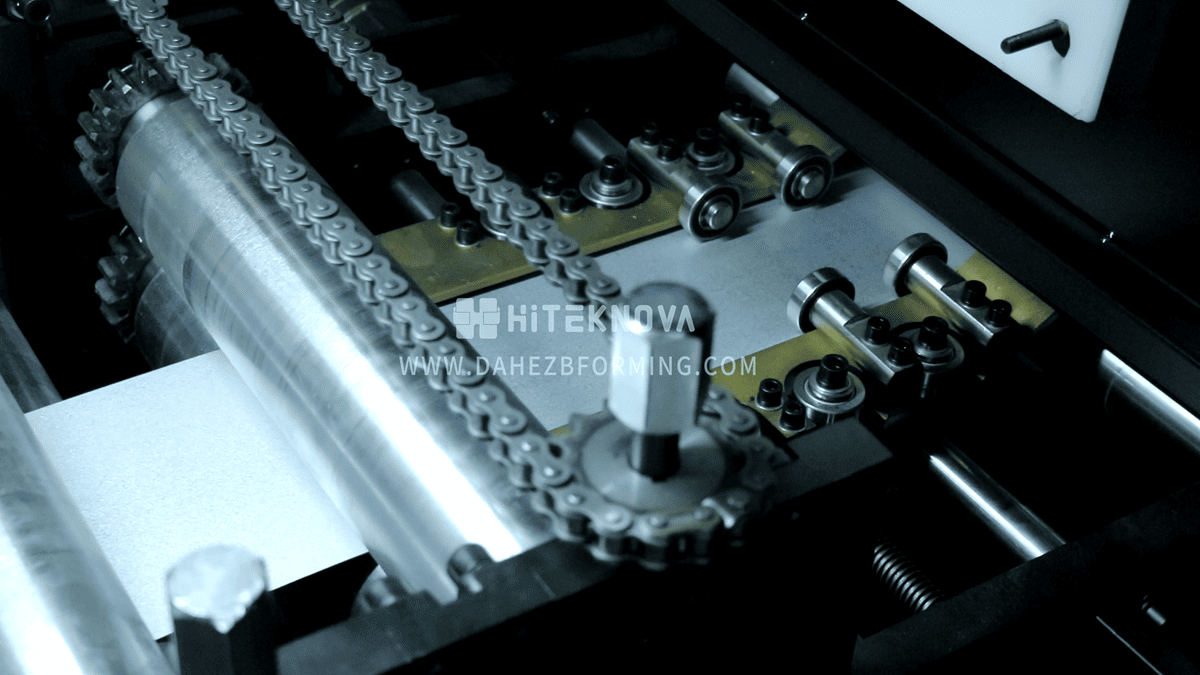

The Motor drive, automatic feeding de-coiler stretches the center outward, ensuring that the raw materials remain tight and feed smoothly into the machine.

Dahezb’s leveling device consists of two upper groups and three lower groups, effectively smoothing the material. The guide wheel ensures stable and consistent feeding.

Equipped with our servo motor drive, the system enables more precise, efficient, and user-friendly punching operations. It supports various applications, including dimple punching, web notches, service holes, web holes, flange cuts, and more. The punching precision is maintained within ±1 mm.

During idling, the maximum speed can reach 35 m/min. However, depending on the material properties and the punching process, the speed may vary. Equipped with functions such as straightening, CNC machining, and a 17-component system, the product delivers high precision, fine polishing, and electroplating, ensuring both aesthetic appeal and practical functionality.

Using 16Mpa hydraulic pressure, it can cut Cr12 and Cr12MoV materials.

Marks and item numbers can be printed on the flange side to facilitate piece-by-piece assembly.

A supporting table up to 4 meters long is designed to ensure that the finished steel retains its shape and size, allowing for easy piling and placement of finished products at the rear.

The safety guard covers the whole machine to ensure workers’ safety. Each part of the safety guard is secured with a lock.

The overall use of black, green and white embellishment, more suitable for the factory easy to clean, simple environment.

Application

- 1-3 story residential buildings and villas

- 1-6 story apartments