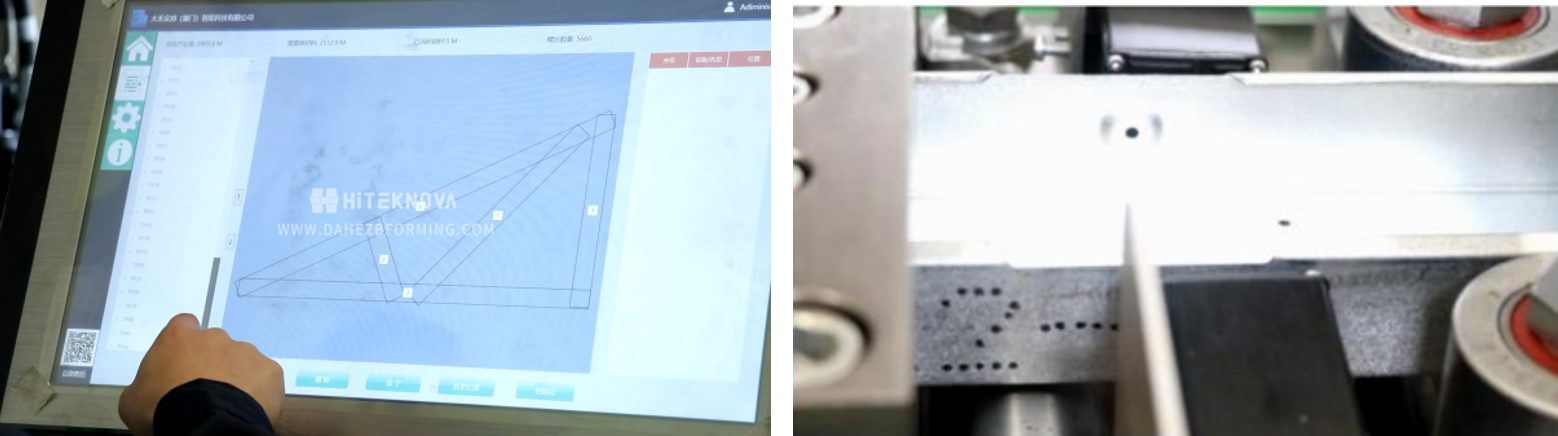

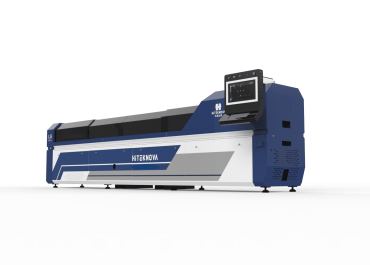

The MF6S-3005 produced by Hiteknova belongs to professional Light Gauge Steel equipment. It is equipped with an intelligent version of the servo motor and can be compatible with construction drawings from different design software. Paired with digital industrial control software, it achieves high efficiency and high standards and is highly intelligent.

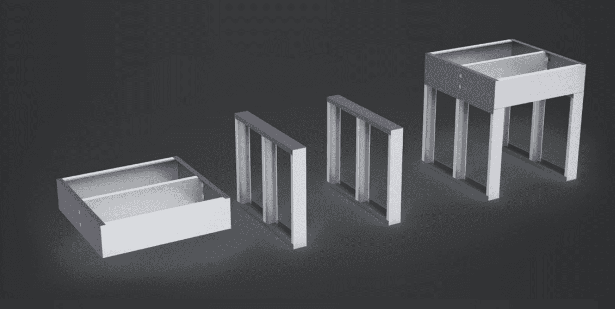

Our MF6S-3005 is specifically designed for manufacturing Light Gauge Steel, trusses, walls and floor slabs for high-rise residences, villas and apartments. It focuses on the production of floor slabs for 1-3-storey residences/villas, 1-6-storey apartments and 1-8-storey commercial buildings. It is an ideal choice for the production of high-rise floor slabs and can be suitable for CC & CU type systems. It can provide you with a fully automatic building system that features low cost, less waste and multiple specifications.

Specification

CC/CU:

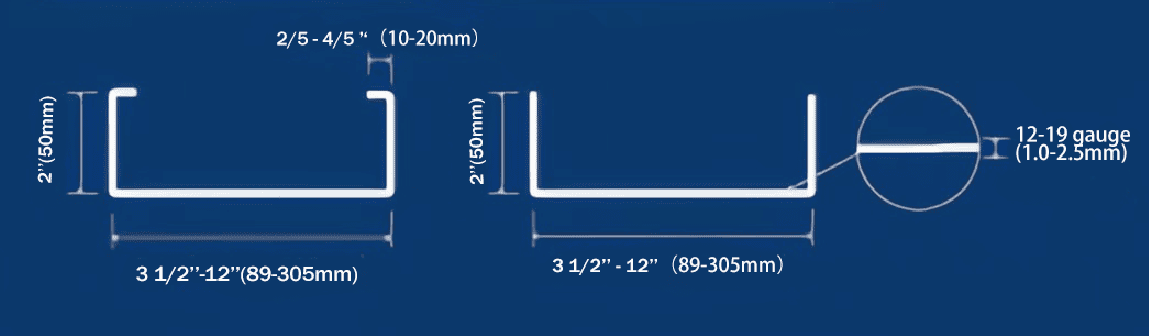

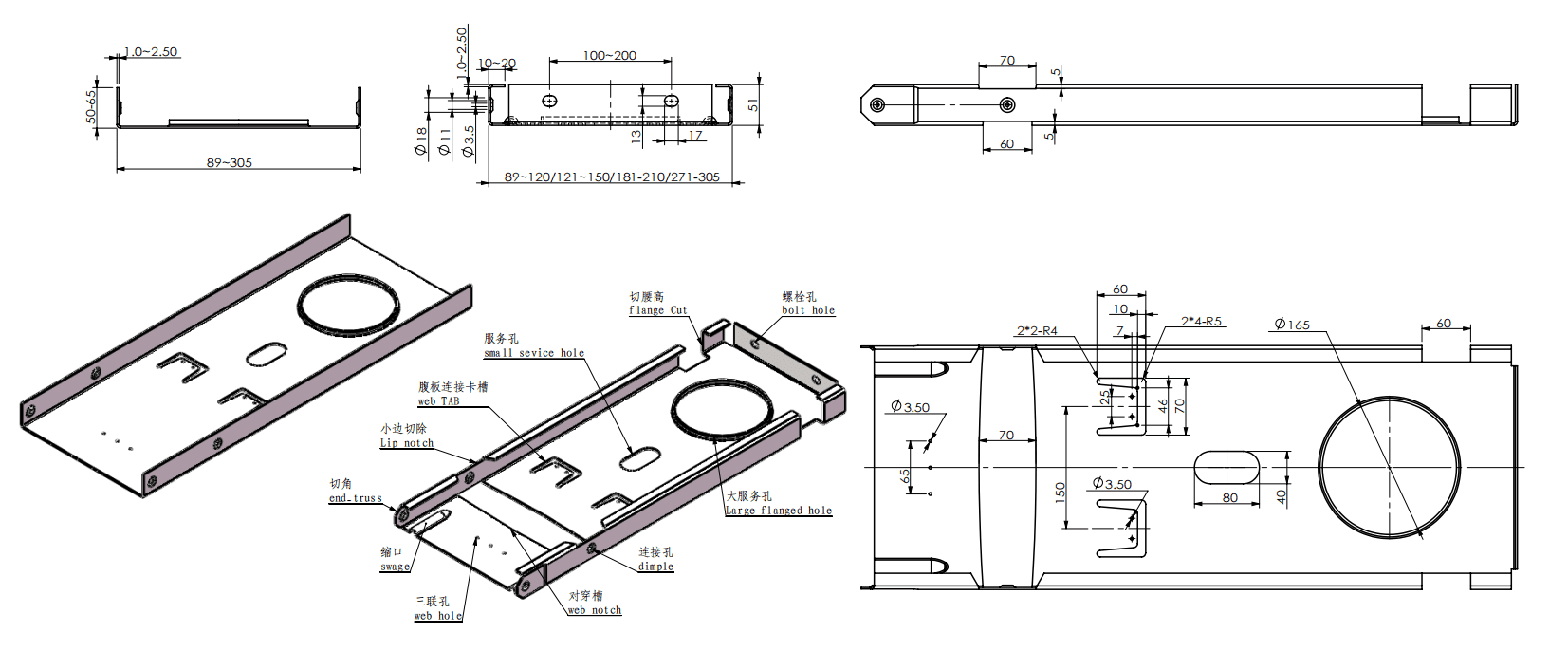

“U” Profile Dimensions

Profile Height (flange): 50-65mm

Profile Width (web): 89-305 mm

“C” Profile Dimensions

Profile Height (flange): 51 mm

Profile Width (web): 89-120/121-150/181-210/271-305 mm

Profile Lip: 10-20 mm

Material Thickness: 1.0-2.5 mm,Q235、G550(Thickness less than 1.6mm)hot-rolled galvanized steel strip

Changing sizes: Full-automatic (Dimensions can be changed automatically by PLC control)

Technology Parameters

| Machine Weight | About 18T |

| Profile Shape | CC and CU |

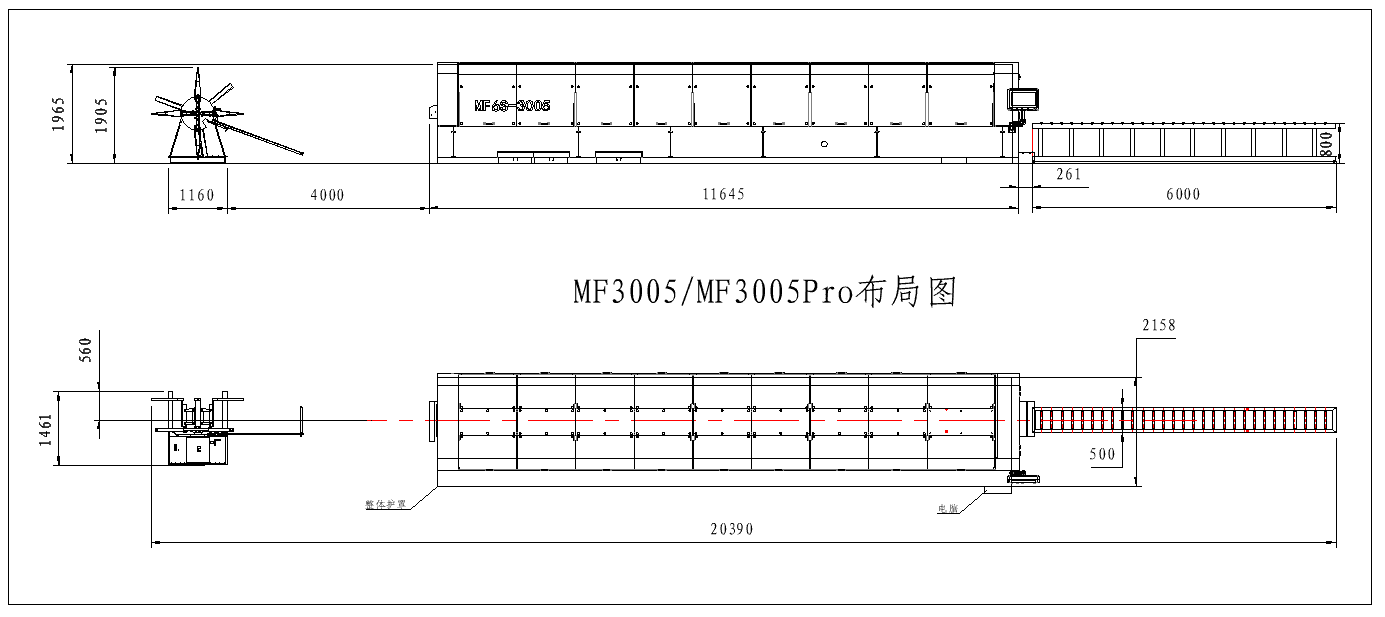

| Dimension of forming parts | (length) 11.0m x (width) 1.9m x (height) 2.0m |

| Section steel material | Q235,Q345,G550,Hot-tied galvanized strip steel |

| Leveling device | 2 groups for upper and 3 groups for down. |

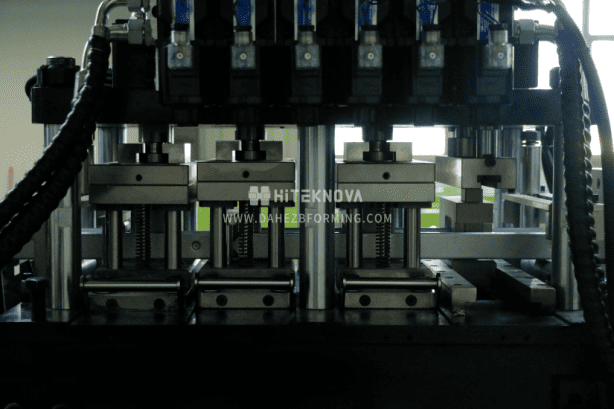

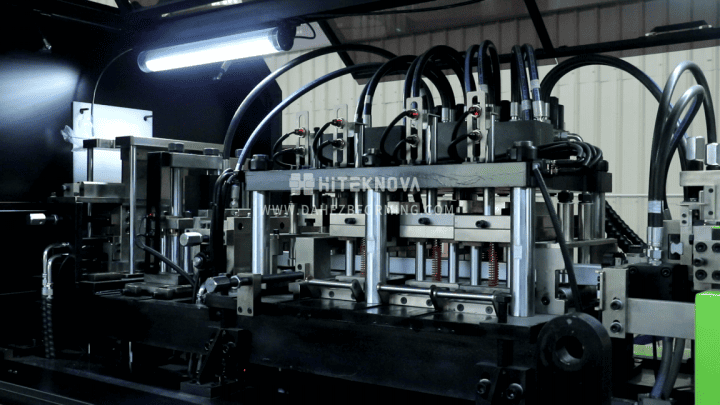

| Punching type | hydraulic punching |

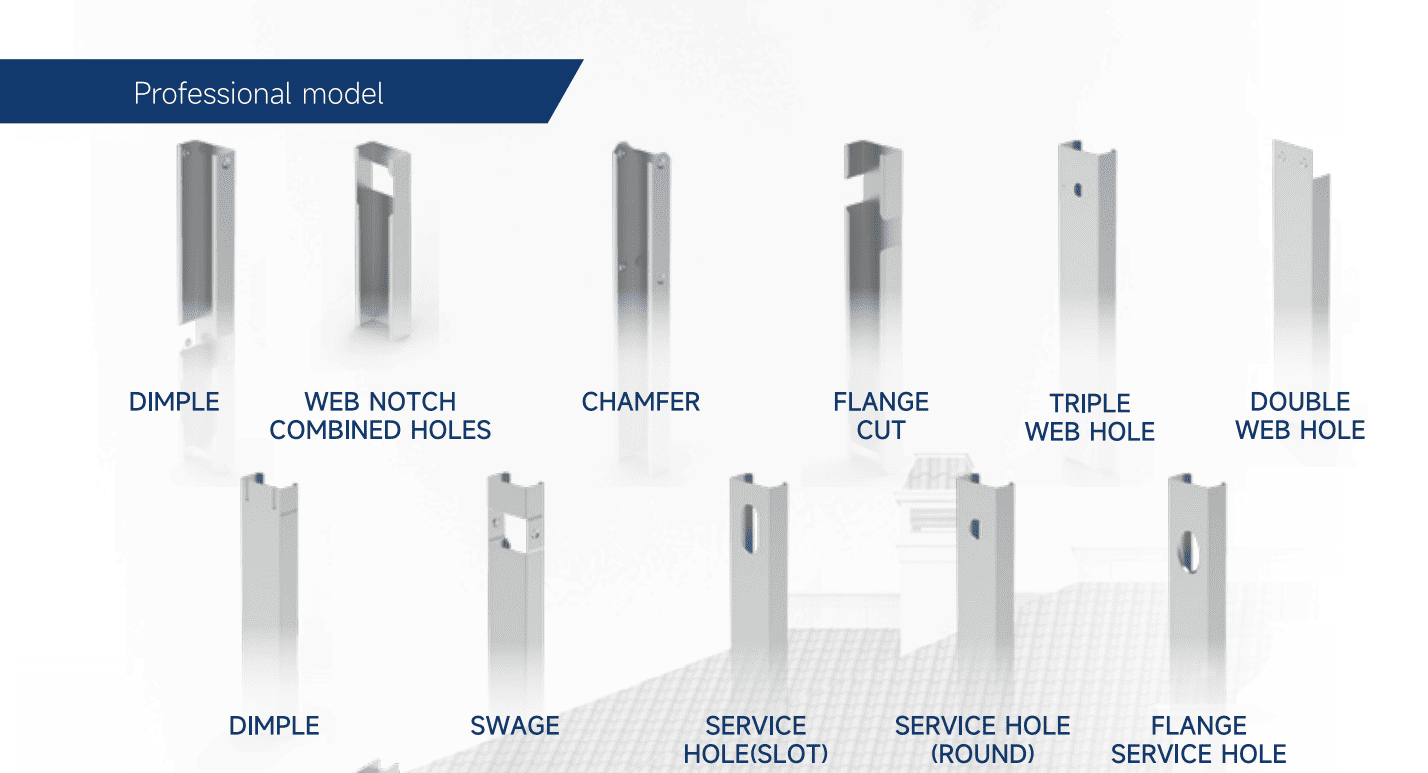

| Hole Type | 1、end truss

2、swage 3、web hole 4、dimple 5、web notch 6、large service hole 7、bolt hole 8、flange cut 9、small service hole 10、web tab 11、lip notch 12.Inline Expandable Punch Die (for specifications 150 and above) 13.Offline End Flanging Die; |

| Control system | PLC Control |

| External controller | 1 |

| Drive | Servo motor 22KW+arc bevel gear reducer |

| Main hydraulic station | Hydraulic station power 11KW+air-cooled |

| Main forming | 19 Composition type |

| Out-let Table | 12m |

| Cutting material | Cr12MoV |

| Hydraulic Pressure | 16Mpa |

| Inkjet printing | Online inkjet printing system |

| Free Spare Parts | Easy wear parts |

| Specification book | 1 |

| Machine color | Main body gray, red trim, frame gray black, with integral protective cover |

Production flow:

- De-coiler→ Feed And Leveling Device→ Hydraulic punching→ Roll Forming System→ Hydraulic Cutting→ Product Support Frame

Profile Drawings

| Standard Metric Sizes | |

| Web Width | 89-305 mm |

| Flange Height | 41/51/61mm |

| Lip Width | 10-20 mm |

| Max Material Thickness | 1.0-2.5 mm,Q235、G550(Thickness less than 1.6mm) |

| End truss | 1.0-2.5mm |

| Lip Cut | 60mm and 70mm |

| Web Hole | Φ3.50mm |

| Dimple | 17mm |

| Web Notch | 70mm |

| Large Service Hole | Φ165mm |

| Standard Imperial Sizes | |

| Web Width | 3.5″-1.20’’ |

| Flange Height | 1.6″ 2″ 2.4″ |

| Lip Width | 0.39″-0.72″ |

| Max Material Thickness | 0.039″-0.098″,Q235、G550(Thickness less than 6.29″) |

| End truss | 0.039″-0.098″ |

| Lip Cut | 2.36″ and 2.75″ |

| Web Hole | Φ0.13″ |

| Dimple | 0.66″ |

| Web Notch | 2.75″ |

| Service Hole | 6.49″ |

- Custom Service Holes size available on request

- Custom Bolt Hole sizes available on request

- Custom Web Holes size available on request

- Plate speed: high speed 35m/min, (actual production speed according to the number of holes)

- Changing sizes:Full-automatic (Dimensions can be changed automatically by PLC control)

Detail

- De-coiler:Standard type: manual; Alternative type: semi-automatic, fully automatic, etc.

2. Leveling device:2 groups for upper and 3 groups for down.

3. Punching type: hydraulic punching

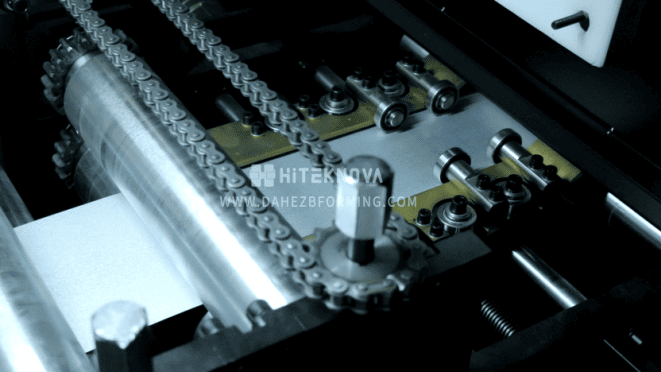

4. Roll Forming System:Servo motor 22KW+arc bevel gear reducer

5. Hydraulic Cutting:16Mpa

6. Marks and Item Number are available to be printed on the flange side for easy assembling pieces to pieces.

7. Out-let Table

8. The computer system is able to read Dahe’s CSV file and connect with machine directly.

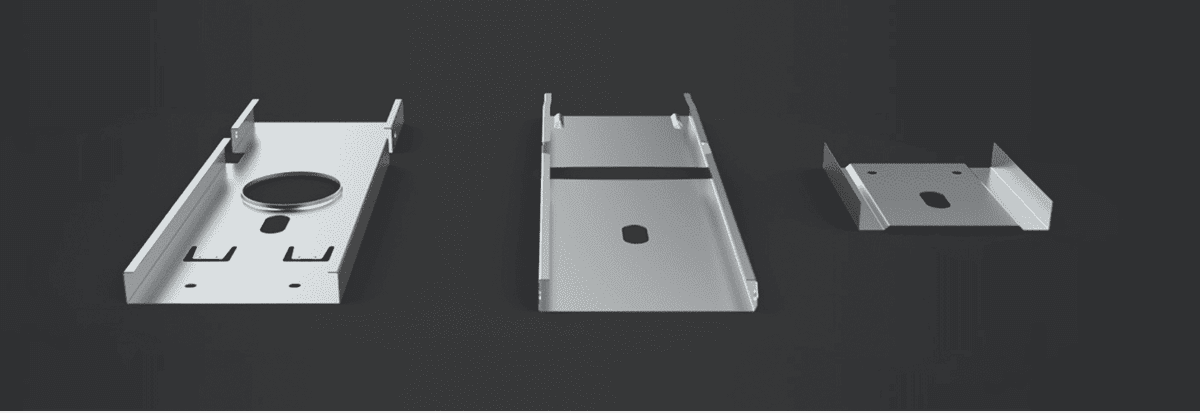

Application