The HITEKNOVA CU600 Series is a specialized and versatile roll-forming system engineered for industrial cable management and electrical infrastructure applications. Designed as a dedicated CU-profile production solution, the CU600 excels in forming wide-format cable tray channels with stable geometry, high precision, and consistent performance. With robust structural capability, broad size adaptability, and reliable production control, the CU600 delivers superior throughput and accuracy for medium- to large-scale cable support system manufacturing.

Supporting flexible transitions across multiple CU profile specifications, the CU600 covers bottom widths of 100 / 200 / 300 / 400 / 500 / 600 mm with web heights of 50 and 100 mm, and handles material thicknesses up to 1.5 mm. Operating at a forming speed of up to 15 m/min, the CU600 ensures dimensional accuracy within strict tolerances, enabling stable, repeatable, and high-quality cable tray production across all supported sizes.

Key Advantages of the CU600

- High-Stability Servo Forming System

Equipped with high-precision domestic servo motor brands, the CU600 ensures stable forming performance for wide-format cable tray channels. The optimized servo control improves forming consistency, enhances product flatness, and ensures reliable geometry across all supported tray widths.

- Upgraded Intelligent Control Platform

A next-generation automation control platform enhances system responsiveness and production logic. The CU600 integrates seamlessly into modern cable-tray manufacturing workflows, supporting digital operation, reduced manual intervention, and intelligent production management.

- Streamlined and User-Friendly Operation

With laptop-based input and a mobile workstation configuration, the CU600 allows operators to manage production flexibly and efficiently. This design simplifies daily operation and supports rapid adjustment for different cable tray specifications.

- Intelligent Fast-Input Software

Automated parameter input allows operators to generate forming programs quickly, minimizing manual programming time and improving production turnaround. This significantly enhances overall manufacturing efficiency for multi-size cable tray orders.

- Digital Auto-Sizing for Multi-Width Cable Trays

The CU600 supports digital automatic size adjustment across bottom widths from 100 to 600 mm. One-touch mode switching ensures safe, stable, and efficient transitions between different tray sizes, reducing downtime and improving operational productivity.

- Cloud-Based Smart Management

Integrated cloud-monitoring capabilities enable real-time visibility of equipment status, production throughput, and workshop performance. Manufacturers can achieve data-driven management, optimize maintenance scheduling, and enhance factory-wide operational transparency.

| Quick detail | |

| Item | Specification |

| Model number | CU600 |

| Machine Function: | Cable tray |

| Drive Motor Power | 11KW |

| Hydraulic Power | 7.5KW |

| Hydraulic Tank | 300L |

| Forming Stages | 20 |

| Line Speed | 15m/min |

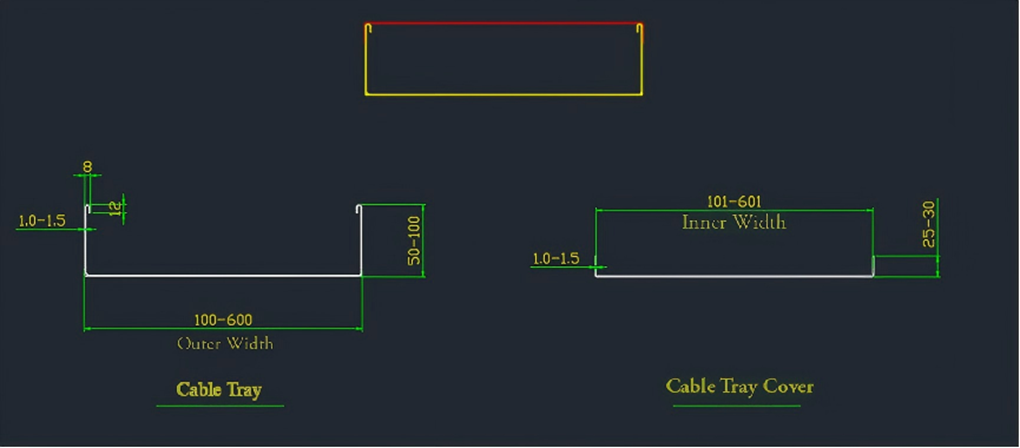

| Products Specification | Size of Profile C、U

Width:100~600mm Height:50-100mm Lip1:8mm Lip2:12mm |

| Thickness | 1.0-1.5mm |

| Driving system | Chain driving |

| Control System: | PLC |

Profile Drawings

Machine Video

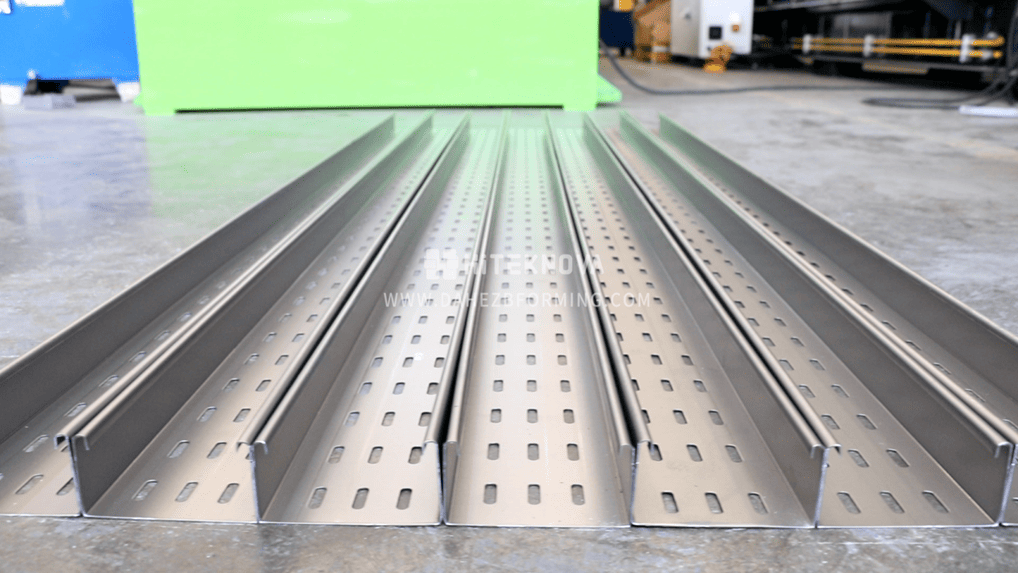

Machine Picture

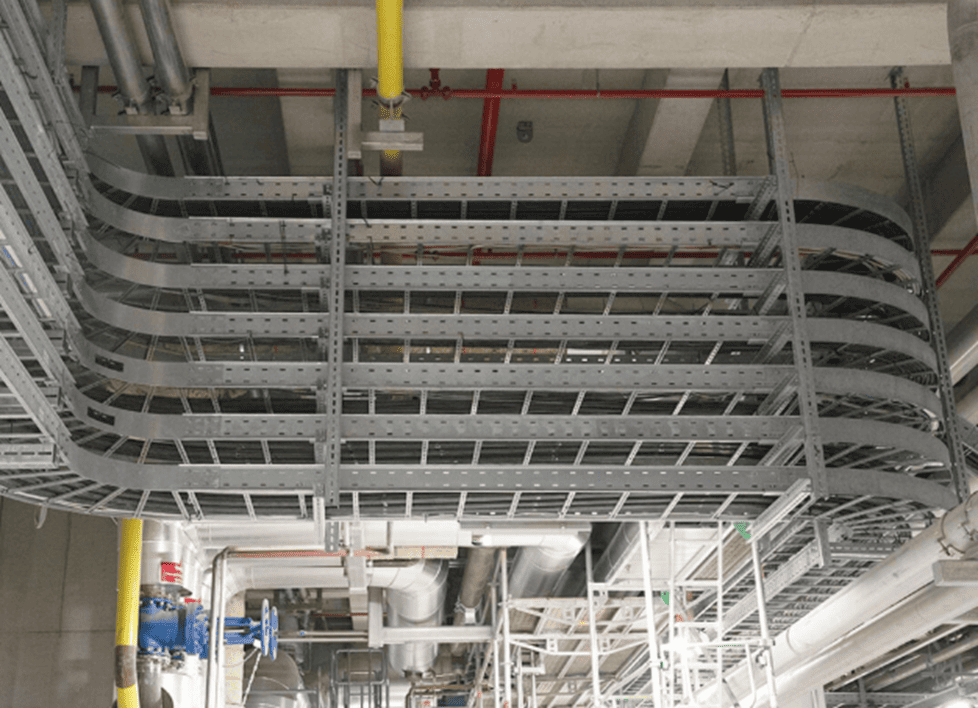

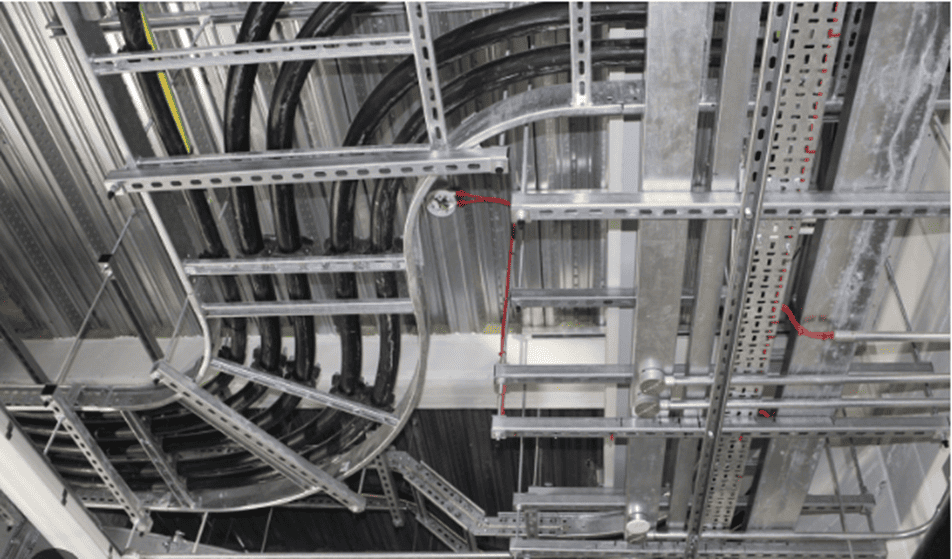

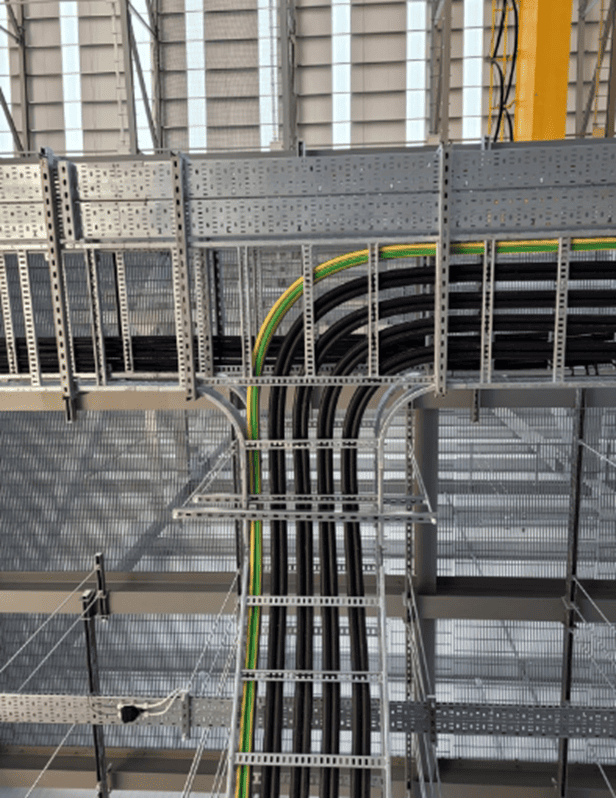

Cable Tray Installation Scenes