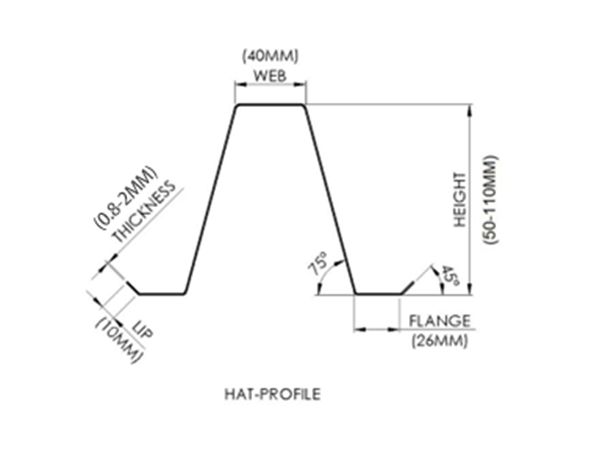

Dahezb newly generation LA series are not only focuses on achieving high-precision production of different base-width steel sections, but also enhances the capability to produce inclined-web profiles, This allows manufacturers to experience the professional and stable output of diverse Hat profiles.

The equipment features a post punching & post shearing + rear shearing design. By changing the different size cutting tools, it can produce the width of 40 mm, web height of 50–110 mm, flange of 20–30 mm, outer flange of 10 mm, and material thickness adjustable between 0.8–2.0 mm.

Our products are widely used in industrial plants and warehouses, photovoltaic support systems, and other steel structure building systems.

1.Machine Technical Specification

| Item | Details |

| Profile | HAT Machine |

| Width | 40mm |

| Height | 50-110mm |

| Flange | 26mm |

| Lip | 10mm |

| Thickness | 0.8-2.0mm |

| Material Type | Hot-rolled strip steel or hot-dip galvanized strip steel |

| Yield Strength | 440MPA |

| Forming Speed | High speed: 28 m/min; Overall working speed: 12–18 m/min (depending on the number of punching holes). |

| Drive Type | Chain Driving Type |

| Production Control System | PLC Control |

| Cutting System | Hydraulic Cutting |

| Forming Stations | 16 Stations |

| Main Motor | 15kw |

| Hydralic Motor | 7.5kw |

| Voltage | 380V/50HZ/3P |

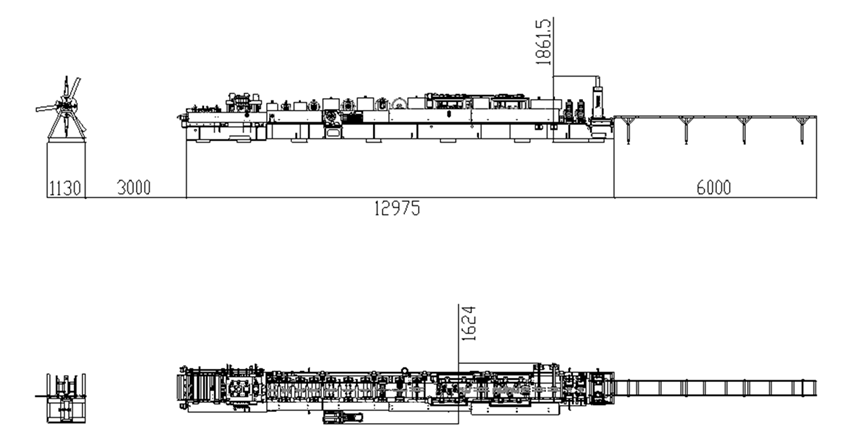

| Equipment Dimension | 11*2.2*1.8m |

2. Flow Chart:

Decoiler – Leveling device – Roll Forming System – Post-cutting – Product Support Table

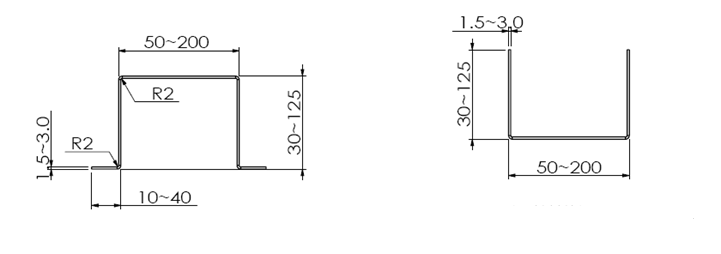

3. Profile Drawing:

LA10

LA30

4:Machine Video

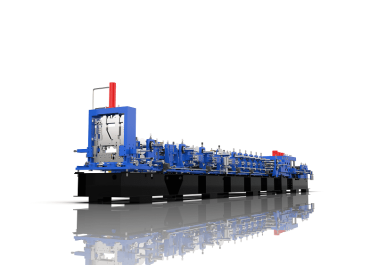

5:Machine Picture