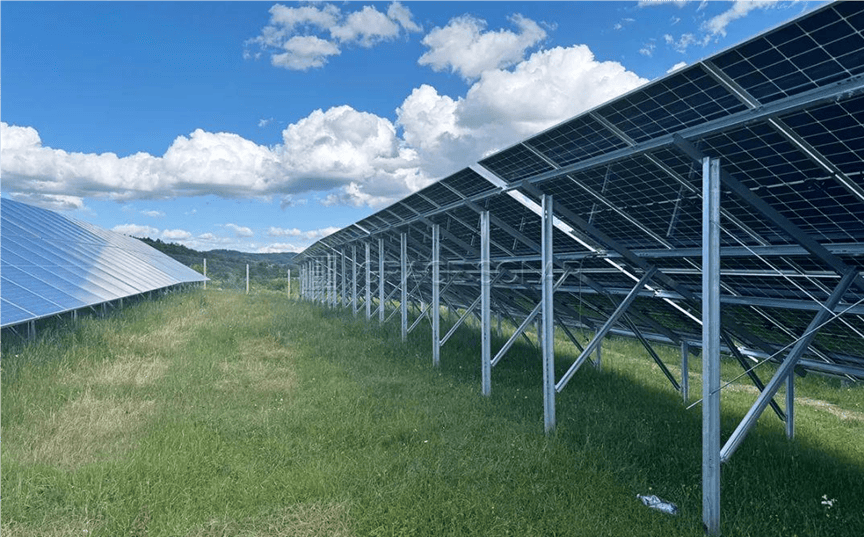

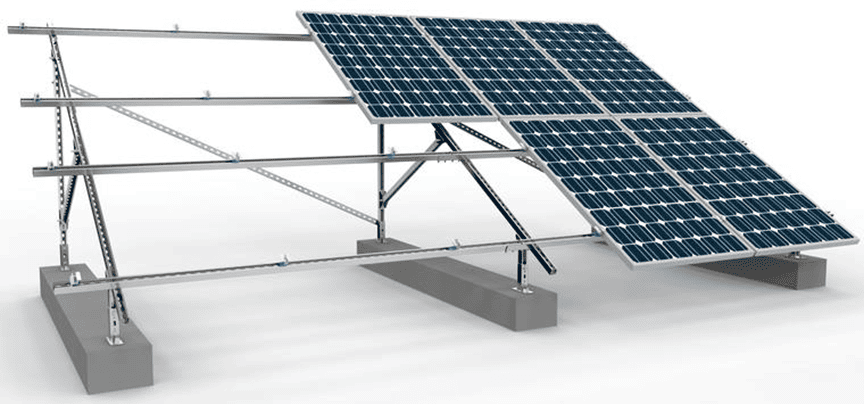

The HITEKNOVA RM41 Series is a high-precision and high-efficiency roll-forming system engineered for solar mounting structure production. Developed as a dedicated profile solution, the RM41 is purpose-built for manufacturing compact, high-strength channel sections widely used in photovoltaic support systems. With excellent forming accuracy, stable geometry control, and continuous high-speed operation, the RM41 delivers outstanding reliability and performance for large-volume solar installation projects.

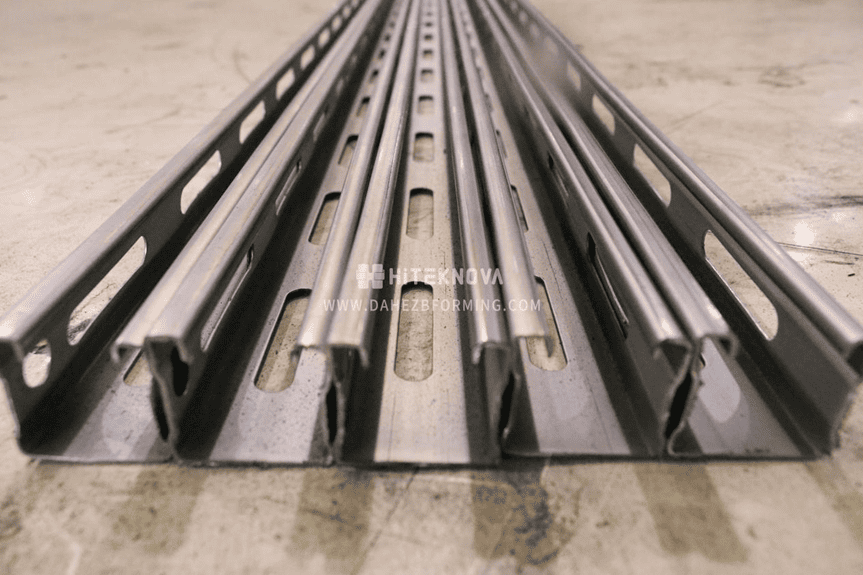

The RM41 supports fully synchronized flying punching and flying cutting, enabling uninterrupted production at speeds up to 35 m/min. It forms channels with a bottom width of 41.3 mm, web heights of 20.63 / 41.3 / 61 / 82.6 mm, and lip dimensions of 9.5 mm and 7.2 mm, accommodating material thicknesses from 1.0–2.5 mm. With punching and length precision maintained within ±0.5 mm.

Key Advantages of the RM41

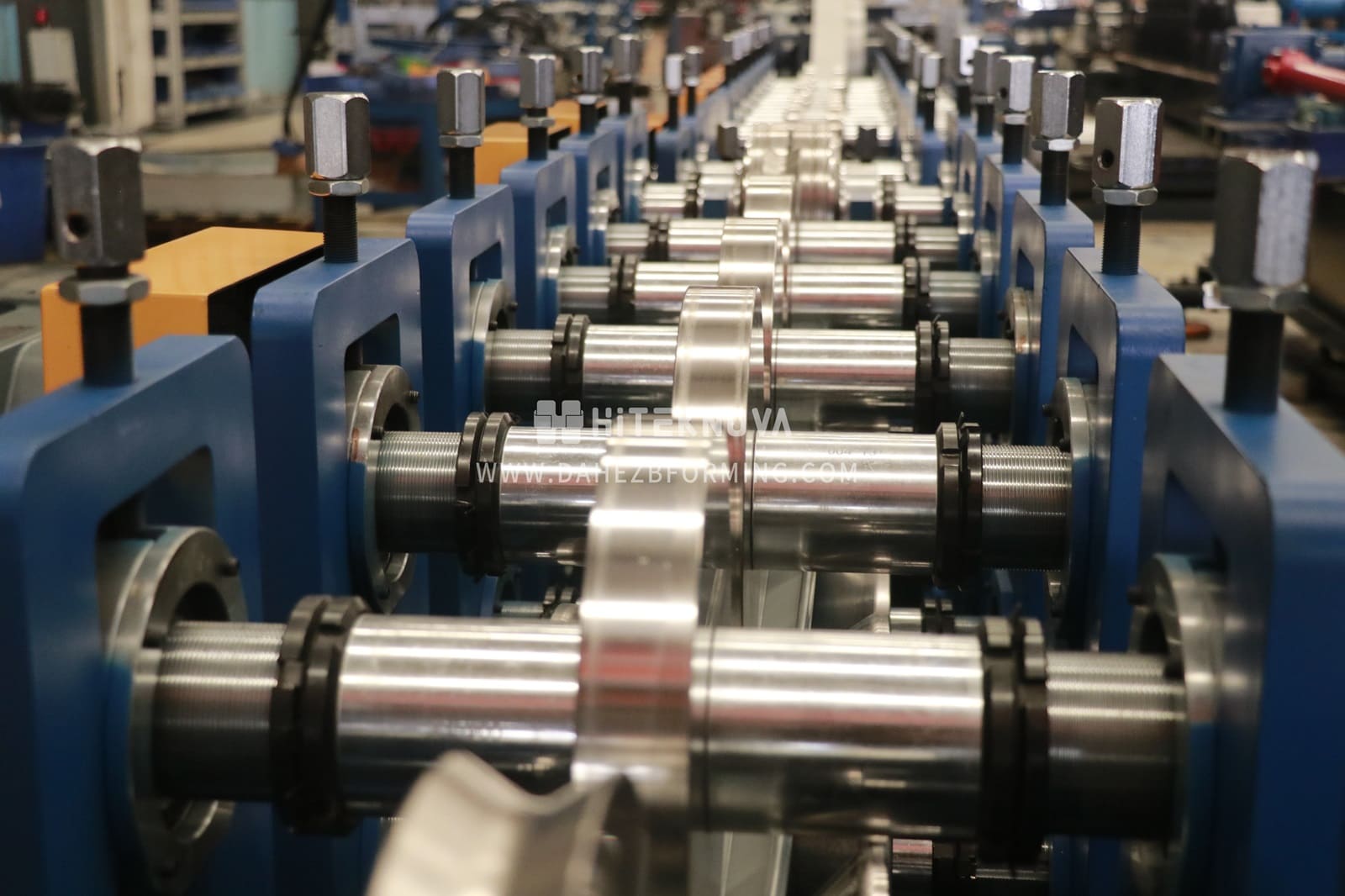

- High-Precision Servo Forming System

Equipped with high-quality domestic servo motor brands, the RM41 delivers exceptional forming stability for small-section solar mounting channels. The optimized servo drive enhances dimensional accuracy, profile consistency, and long-term operational reliability.

- Enhanced Intelligent Control Platform

A next-generation control architecture provides faster response, smoother production logic, and improved synchronization for flying punching and flying cutting. This ensures stable high-speed operation and supports intelligent, data-driven manufacturing workflows.

- Efficient and User-Friendly Operation

With laptop-based input and a mobile workstation layout, the RM41 enables flexible operation and streamlined production management. Operators can quickly adjust parameters, monitor forming conditions, and maintain consistent output with minimal effort.

- Intelligent Fast-Input Software

Automated parameter input significantly reduces manual programming time, allowing operators to generate production recipes rapidly. This enhances daily throughput and supports high-mix, large-volume solar mounting component manufacturing.

- High-Speed Flying Punching & Flying Cutting

The RM41 integrates digitally synchronized flying punching and cutting, enabling continuous forming at up to 35 m/min. Stable, vibration-controlled motion delivers ±0.5 mm accuracy for both punching and overall length, meeting stringent solar mounting tolerance requirements.

- Cloud-Based Smart Management

Built-in cloud monitoring allows real-time tracking of equipment performance, production data, and operational status. This supports predictive maintenance, transparent workshop management, and fully digitalized production oversight.

| Quick detail | |

| Item | Specification |

| Model number | RM41 |

| Machine Function: | solar mounting structure |

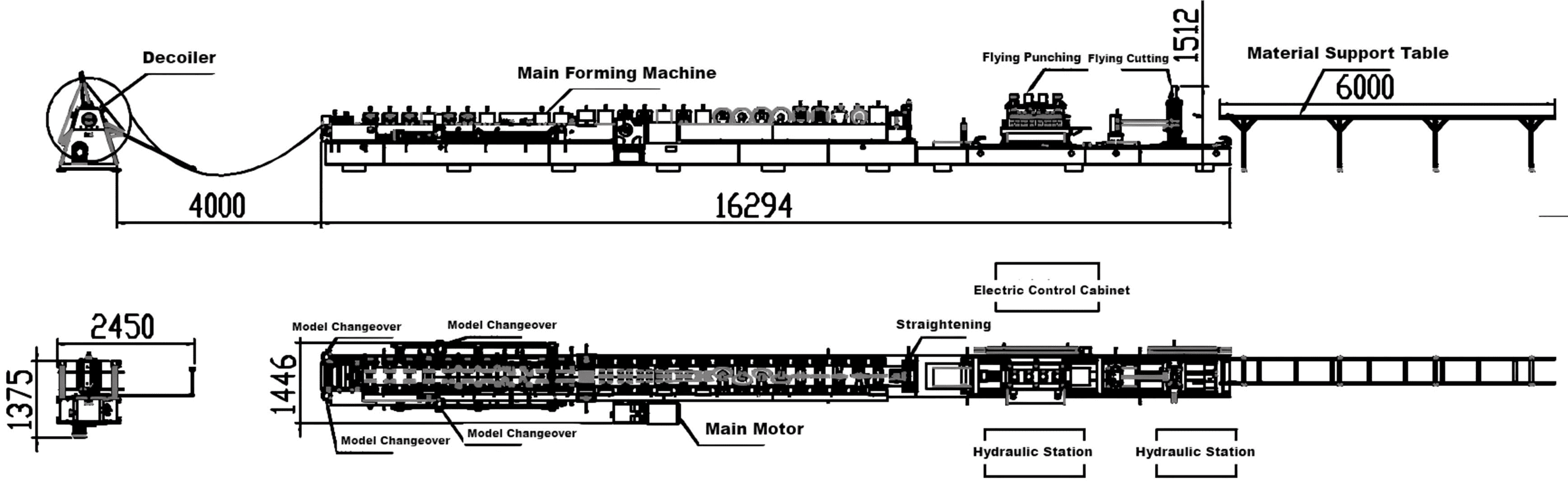

| Dimensions L x W x H | 16.29m x 1.46m x1.5m |

| Weight | 12.5T |

| Drive Motor Power | 30KW |

| Hydraulic Power | 15+7.5KW |

| Hydraulic Tank | 300L*2+150L |

| Forming Stages | 25 |

| Line Speed | 35m/min |

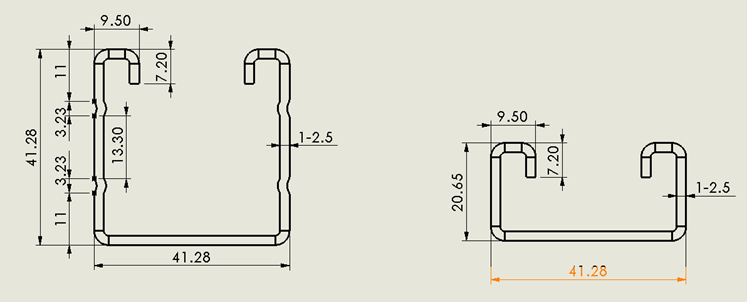

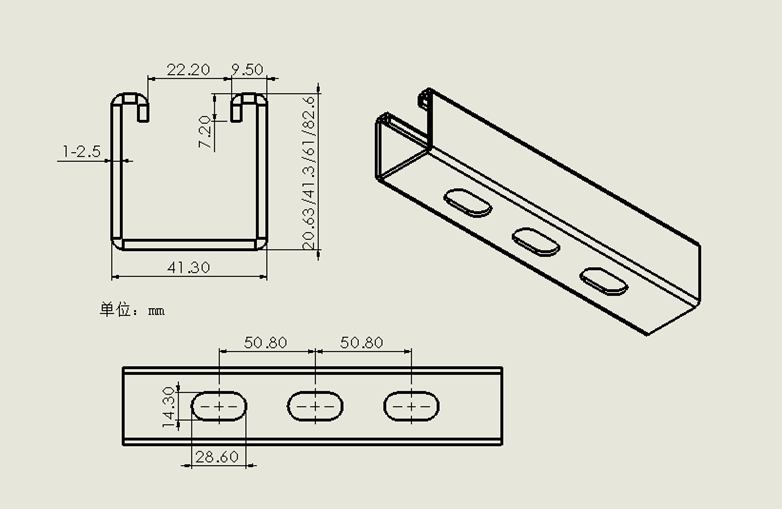

| Products Specification | Width:41.3 mm

Height:20.63 / 41.3 / 61 / 82.6 mm Lip: 9.5 mm and 7.2 mm |

| Thickness | 1.0-2.5mm |

| Driving system | Chain driving |

| Control System: | PLC |

flow chart

Profile Drawings

Machine Video

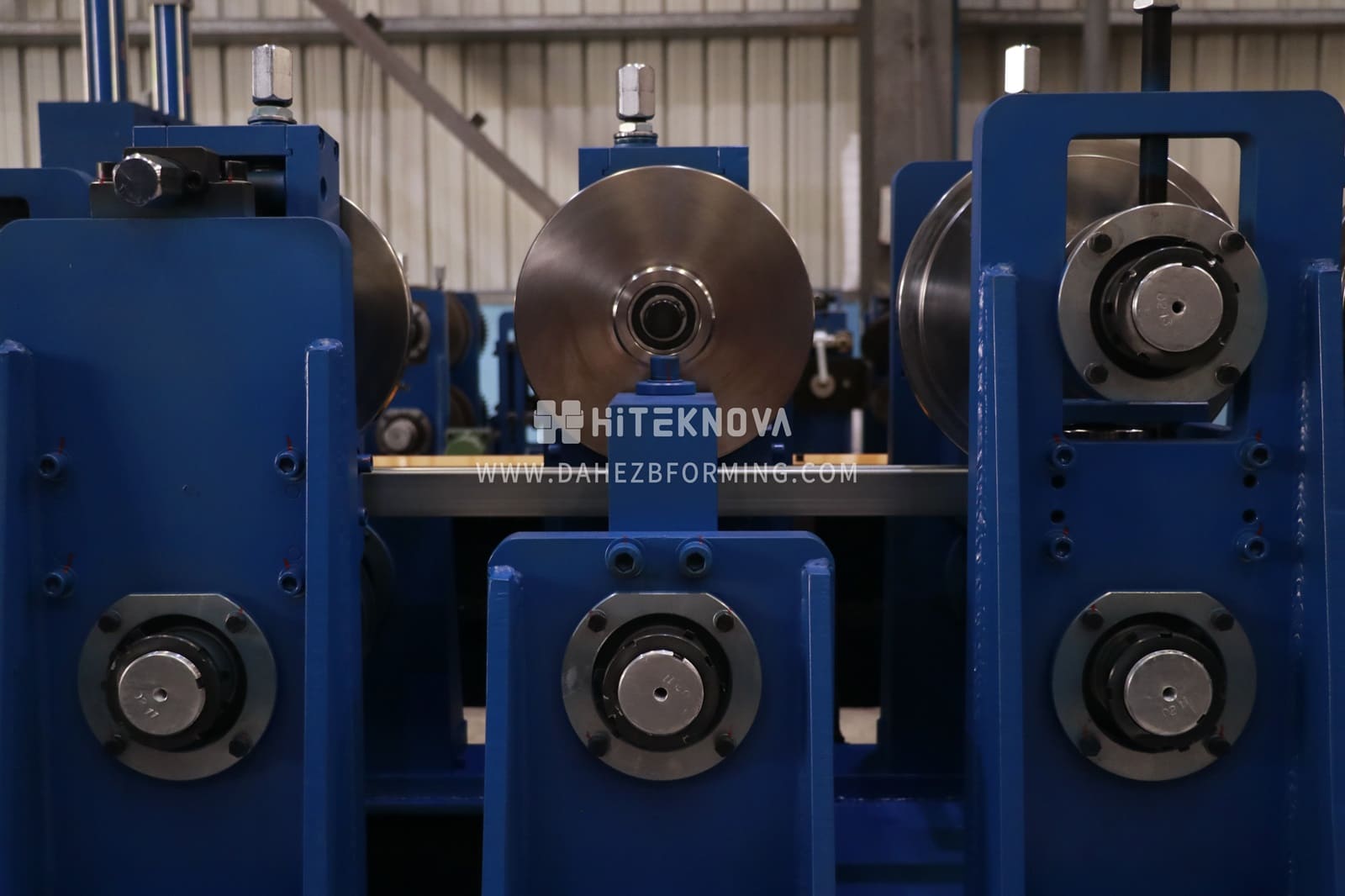

Machine Picture

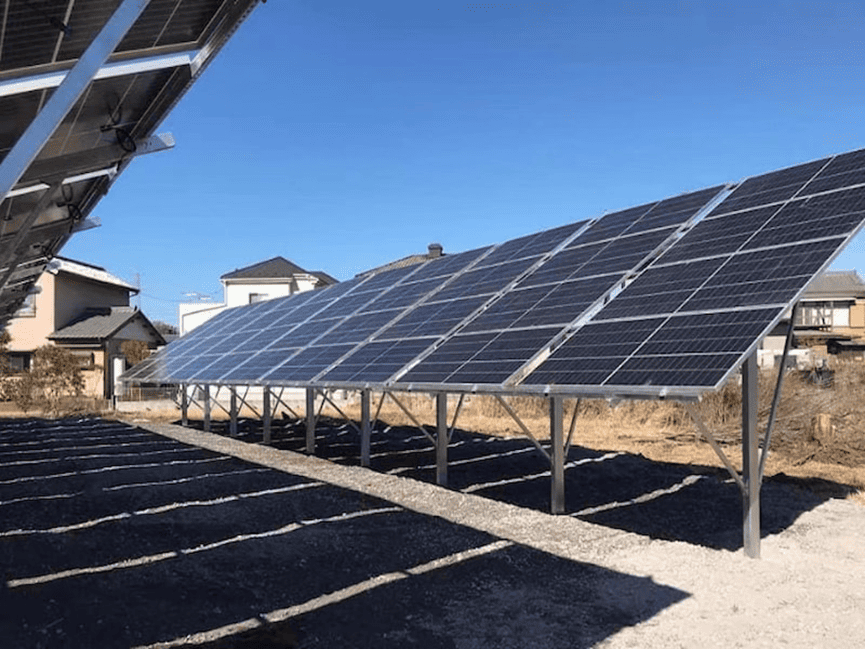

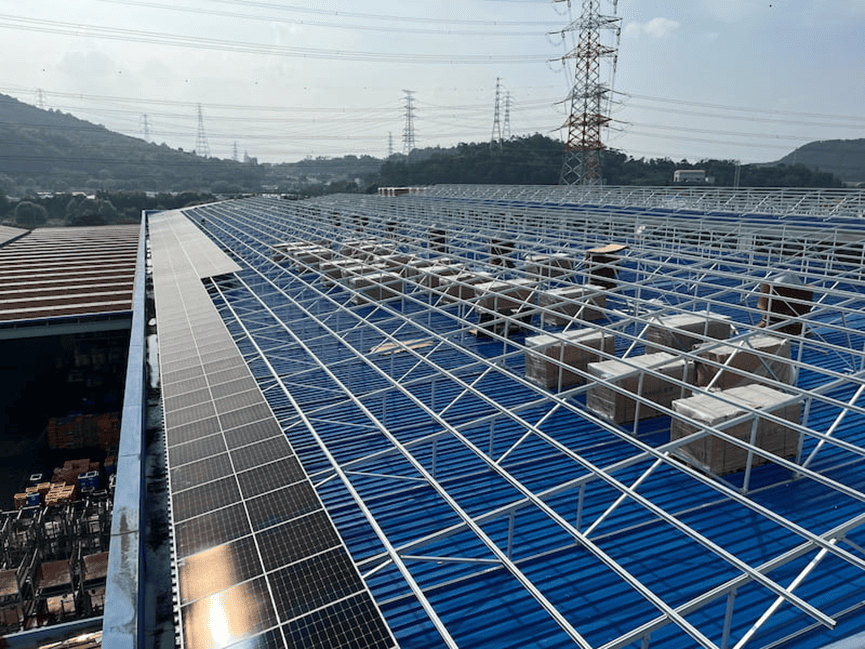

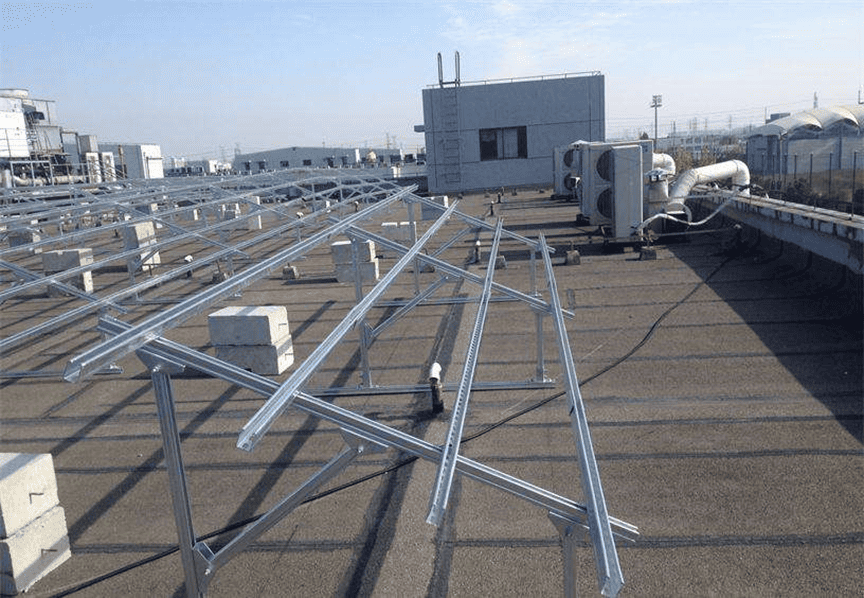

Installation