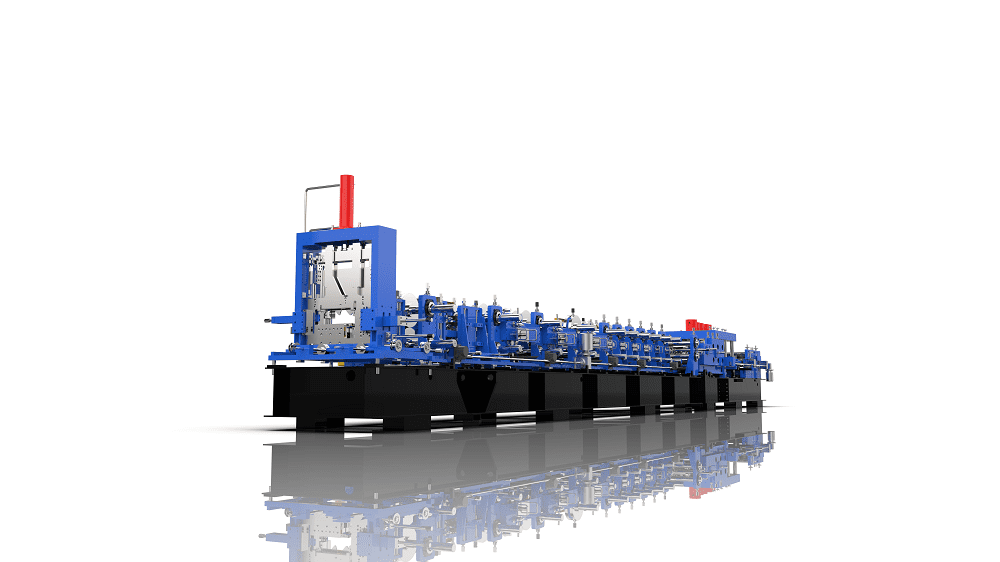

Best CZ Purlin Roll Forming Machine with 10-Minute Fully Automatic Quick Change – Dahezb NLT350

Best CZ Purlin Roll Forming Machine with 10-Minute Fully Automatic Quick Change – Dahezb NLT350

Searching for a truly reliable CZ purlin roll forming machine that can switch from C to Z (and any size) in under 10 minutes without manual adjustment?

You just found it.

The Dahezb NLT350 has become the first choice for steel fabricators in over 30 countries who need maximum uptime and minimum downtime.

Why 10-Minute Fully Automatic Quick Change Changes Everything

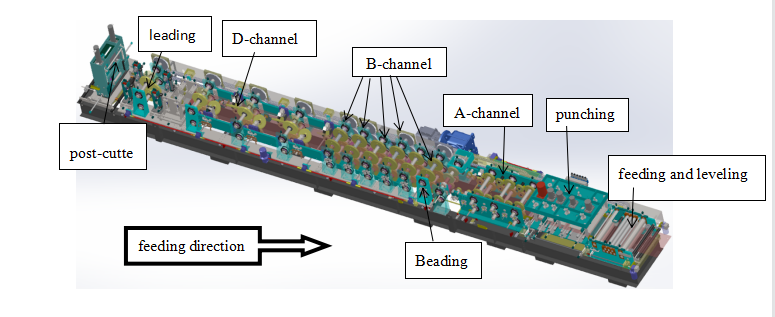

Most traditional lines require 40–60 minutes (sometimes full manual work) to switch profiles. With the NLT350 servo-driven system, the entire C↔Z conversion and size change is completed in ≤10 minutes with one-button operation.

Result for fabricators worldwide:

- Hundreds of saved labor hours every month

- Ability to run small & mixed batches profitably

- Faster project delivery, happier clients

Core Advantages of the NLT350 CZ Purlin Machine

| Feature | Benefit to You |

|---|---|

| ≤10-minute full auto size change | Run C80-350 & Z100-350 on the same line, no delay |

| 25 m/min production speed | Higher daily output than 90% of machines on market |

| Non-stop hydraulic pre-punch + cut | Zero speed loss during punching |

| Siemens PLC + Yaskawa servo | Proven stability in 50°C desert or -20°C winters |

| 1.5–3.5 mm thickness range | Handles both light gauge and heavy structural steel |

| CE & ISO9001 certified | Zero customs issues in EU, USA, Brazil, Australia |

| Lifetime remote technical support | 24/7 engineer team, any time zone |

Real Projects Running NLT350 Machines Right Now

- 100,000 m² logistics warehouse – California, USA

- Multi-span industrial factory – São Paulo, Brazil

- Cold storage distribution center – Munich, Germany

- Large-scale steel framing project – Dubai, UAE

- Agricultural processing facilities – Buenos Aires, Argentina

All running 2–3 shifts daily with zero unplanned downtime.

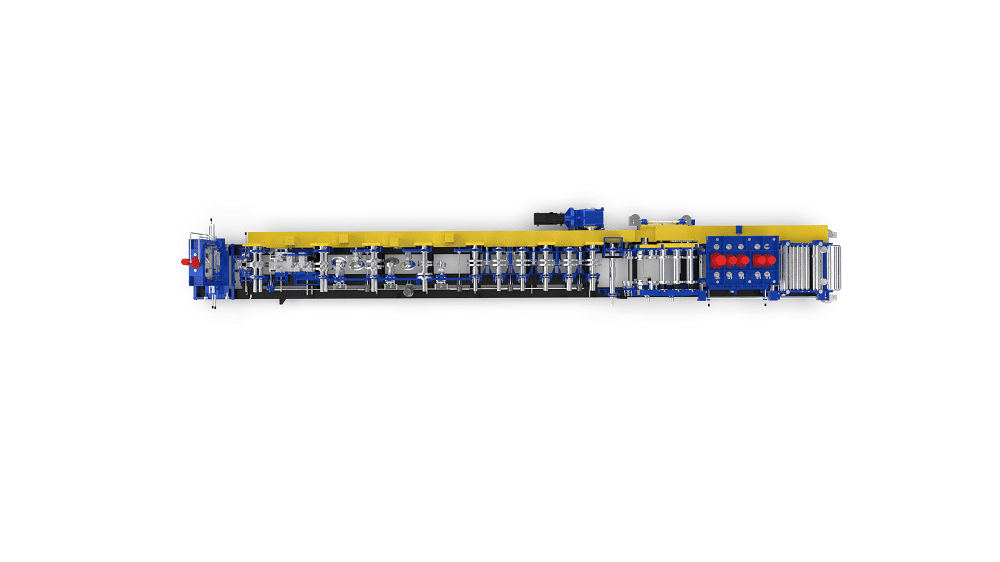

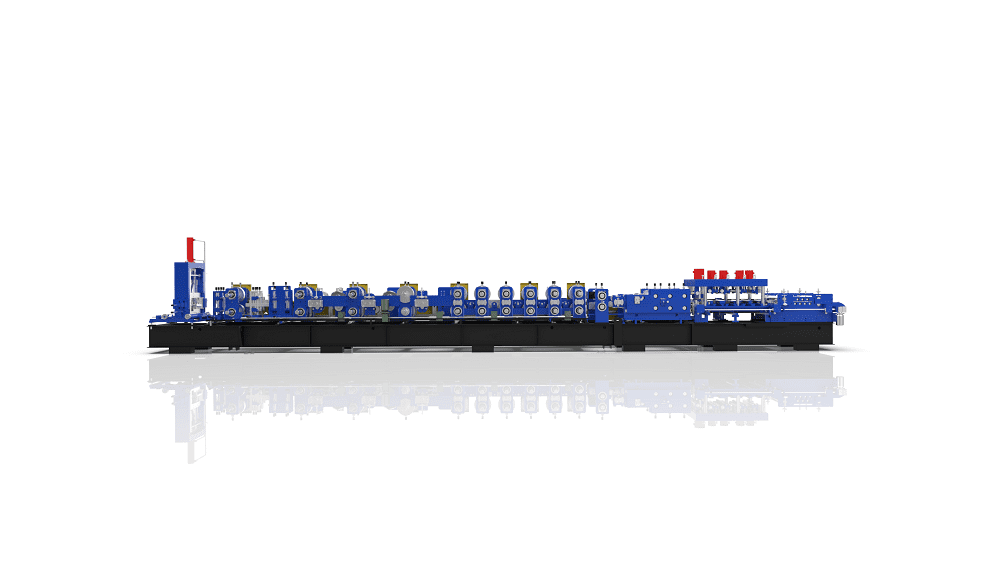

Technical Specifications (Most Popular Configuration)

- Profile range: C80–350 mm | Z100–350 mm

- Material: Galvanized, pre-painted, hot-rolled coil

- Thickness: 1.5–3.5 mm

- Punching: Hydraulic non-stop, any hole pattern

- Cutting: Hydraulic pre-cut or post-cut

- Control: Siemens touch screen + remote diagnosis

- Power: 22 kW main motor + 15 kW hydraulic station

What You Get When You Choose Dahezb

- Free layout design & foundation drawing

- Full installation and training (on-site or remote)

- 12-month warranty + lifetime spare parts supply

- Spare parts stock in Spain warehouse (7-day delivery to Europe)

- Weekly container shipping to all major ports

Ready for Your Factory-Direct Quotation?

Just send us three quick details:

- Your country & nearest port

- Material thickness you use most

- Approximate monthly output needed

Our engineer will reply within 2 hours with:

- Exact factory price

- Customized line layout

- Shipping cost & delivery schedule

↓ Talk directly on WhatsApp – response in English | Español | Português | العربية | Русский

[Get My Factory Quote Now → WhatsApp +86 18150105707]

We load containers every week to Los Angeles, Rotterdam, Santos, Dubai, Sydney, Durban, and more.

Dahezb – 18 years, 5,000+ machines running in 30+ countries. Your next production line starts here.