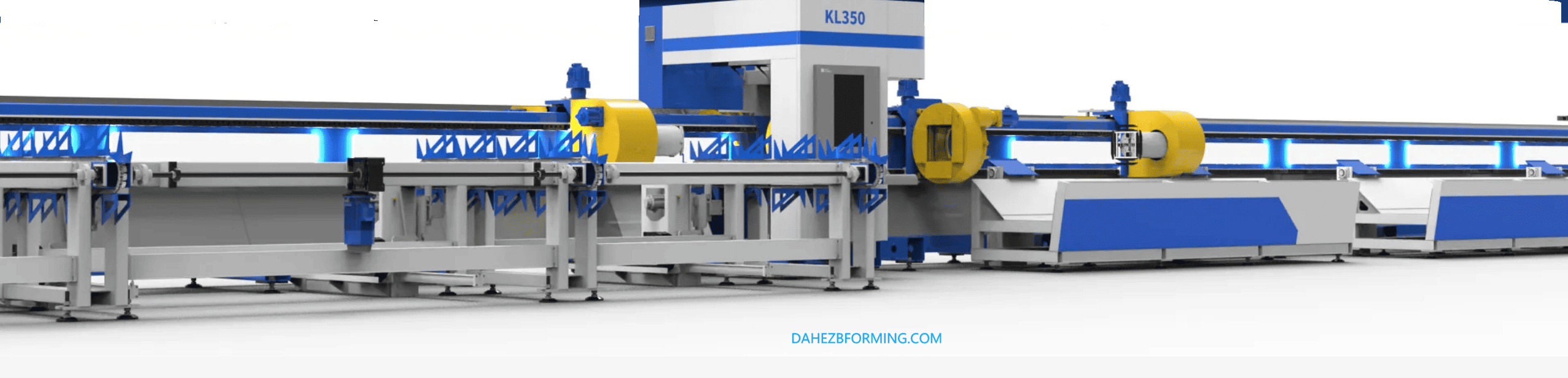

The KL-350 is a high-speed cutting machine designed for precision and efficiency. Built for durability and stable performance, it delivers fast, accurate cuts for metal and other industrial materials, making it ideal for modern manufacturing and fabrication applications.

KL-350 features:

-

Automatic feeding, conveying, cutting, and unloading.

-

Capable of cutting various metals, including stainless steel and carbon steel.

-

Handles round tubes, square tubes, rectangular tubes, channels, H-beams, and special-shaped profiles.

-

Fully automated intelligent processing with no programming or manual intervention required.

-

Modular design with customizable solutions.

-

Integrated advanced robotics hardware and software, precisely aligned with production requirements.

Machine Video:

Key Advantages:

-

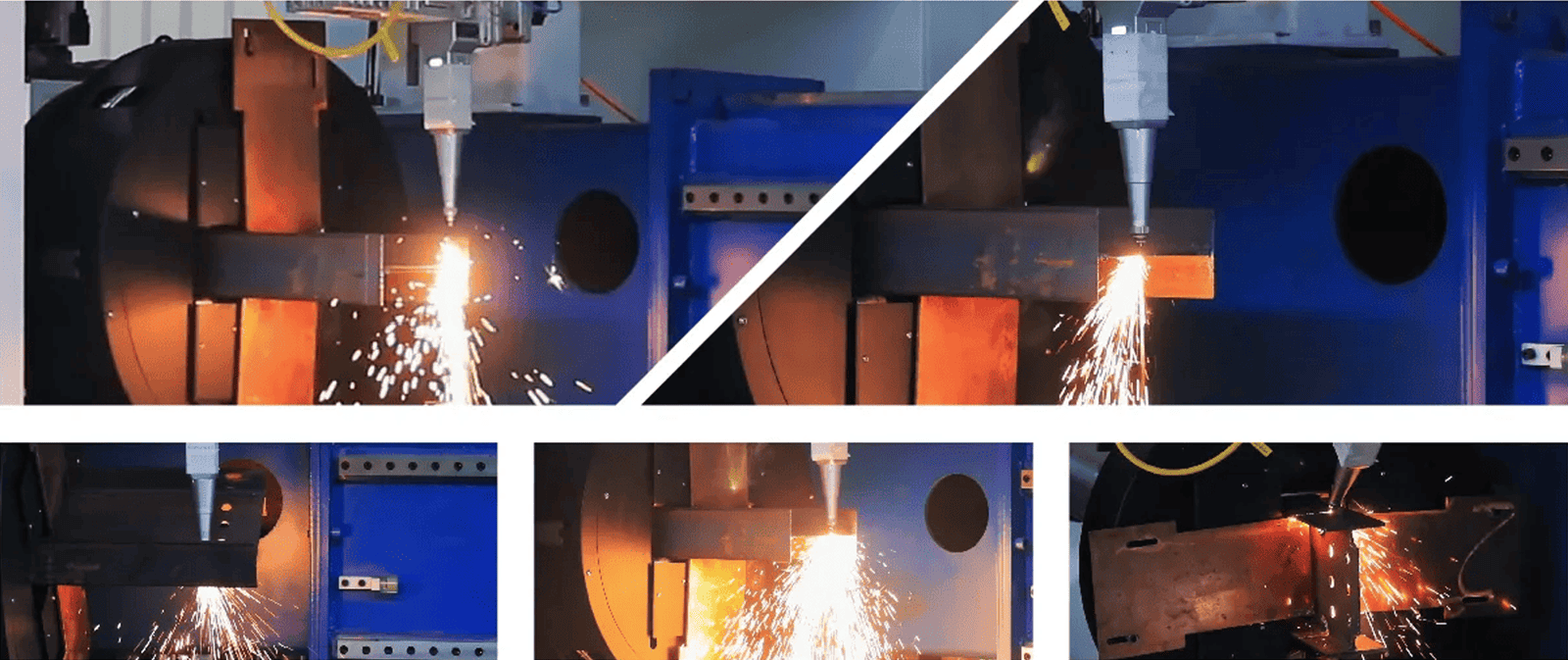

Small Heat-Affected Zone: Laser cutting produces a minimal heat-affected zone. Its high energy density melts material quickly without causing deformation, resulting in smooth and aesthetically pleasing cut edges.

-

High Energy Density: Laser processing delivers high energy in a short time, with minimal heat-affected area, low thermal deformation, and low thermal stress, ideal for precision machining.

-

Wide Applicability: The high energy density of lasers can melt any metal, making it suitable for materials with high hardness, brittleness, or melting points.

-

Low Cost: Continuous large-scale processing reduces the per-part production cost.

-

Non-Contact Machining: Laser processing is non-mechanical, applying no mechanical stress on the workpiece, perfect for precision applications.

-

Intelligent Fast Input Software: Improves operational efficiency, saving 2–3 hours of work daily.

KL-350 Cutting Machine Picture:

KL-350 Cutting Process Demonstration

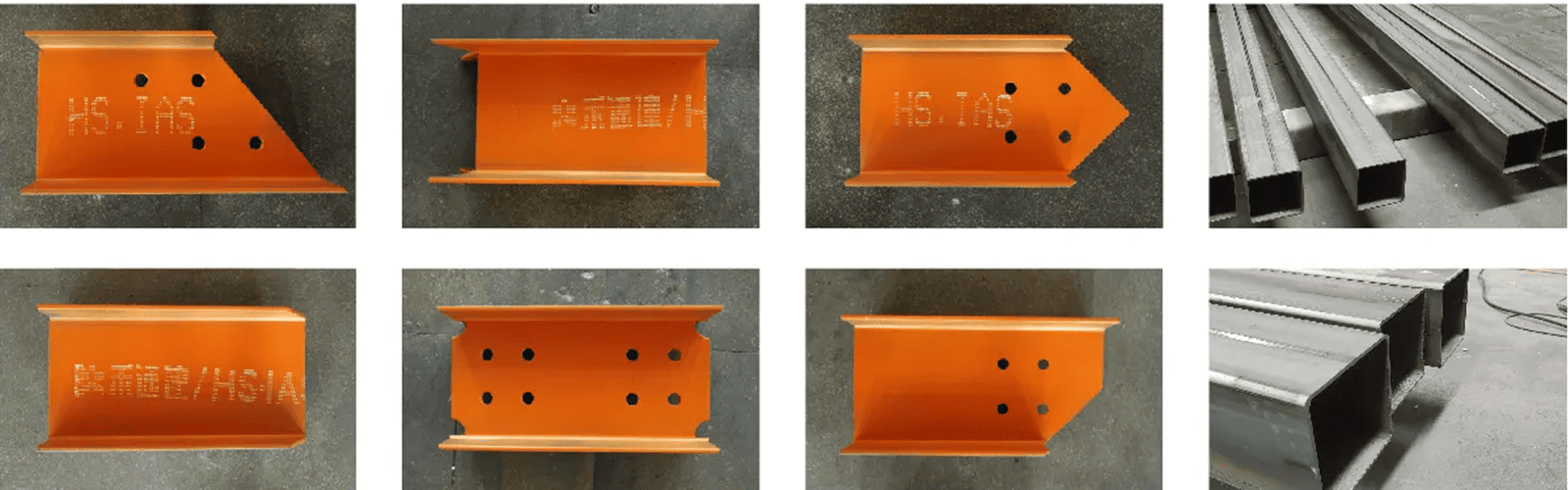

KL-350 Finished Cutting Samples Display

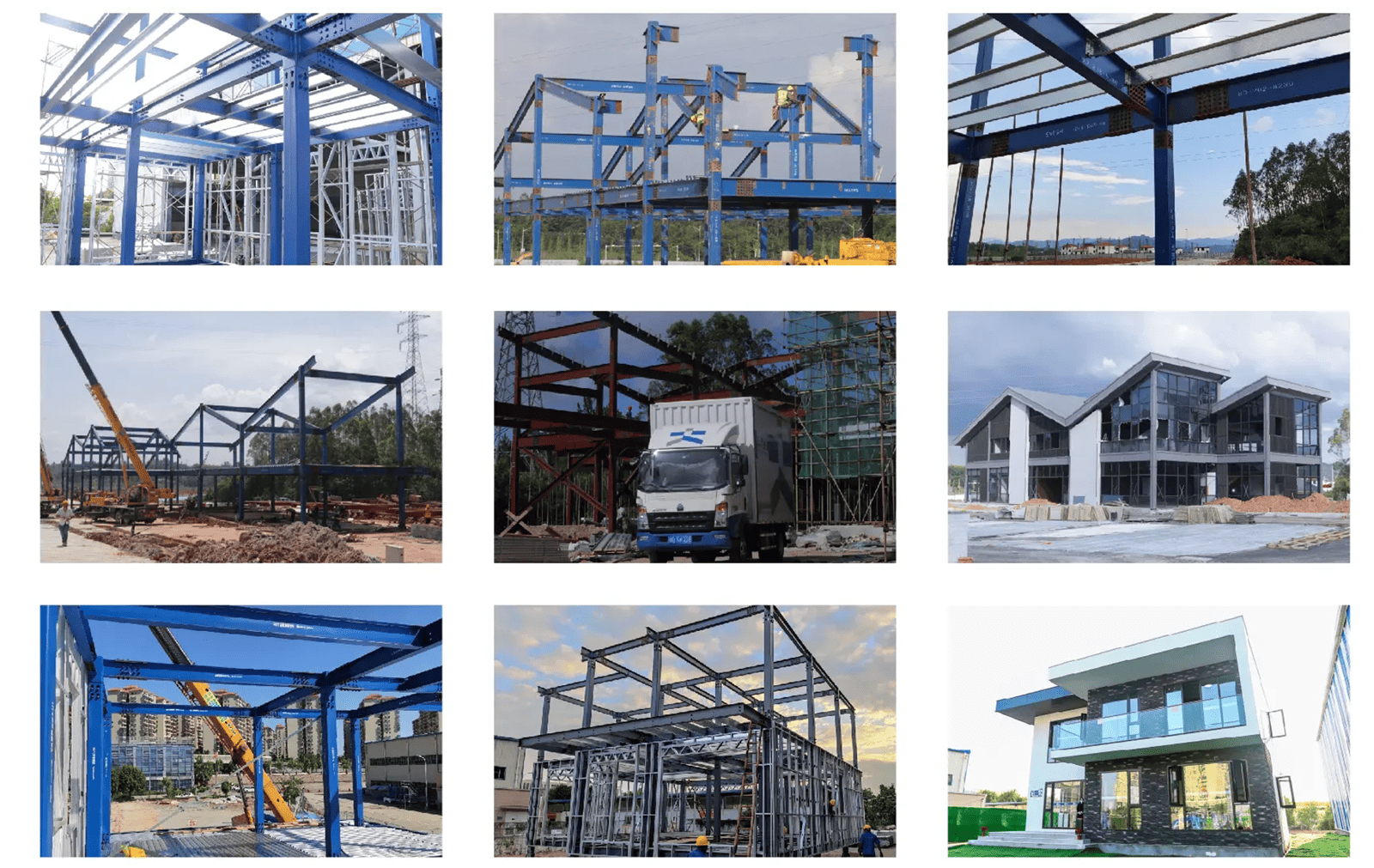

Application