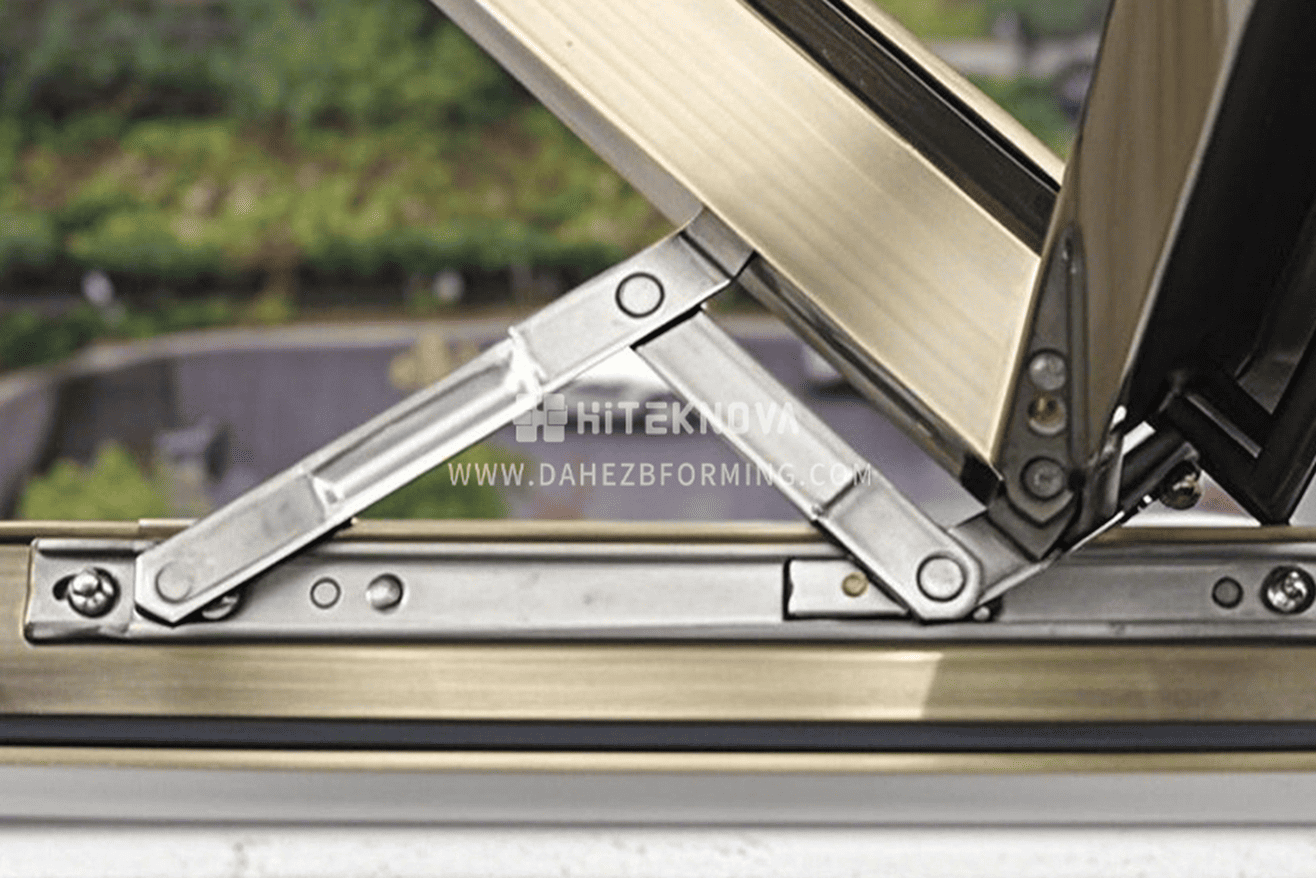

This machine is for C-type hinges—key hardware for doors, windows, and cabinets.It makes hinges with slot widths of 13.5mm, 19mm, 22mm, etc. An advanced servo system ensures stable precision, smooth friction adjustment, and minimal waste. It supports customization for dimensions, specs, and surface treatments.Easy to operate, low maintenance, 25–30 pcs/min speed. Meets strict quality standards—ideal for custom-focused hardware makers.

| Equipment | Parameter |

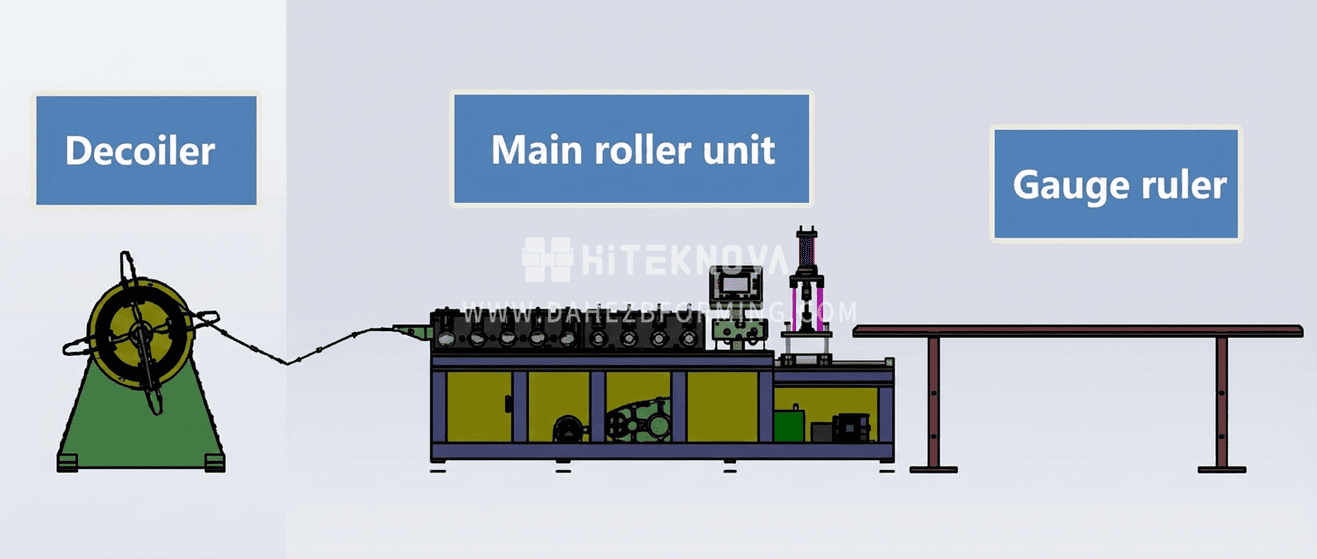

| De-coiler | Material Width:≤200mm

Max Load Capacity:1.5t Feeding Speed:6-10m/min Expansion Mode:Manual Expansion Transmission Mode:Power-Driven |

| Roll Forming Machine | Roller Group Quantity:16 Groups

Roller Material:Gr12MoV Drive Motor:7.5KW Servo Motor Transmission Mode:Gear Transmission Control Mode:Human-Machine Interface Length Fixing Mode:Optical Fiber/Encoder Wheel Production Speed:25-30pcs/min |

| Hydraulic Press | Power:11KW

Punching Frequency:35 Cycles/min Hydraulic Oil Type:No.60 Hydraulic Oil Cooling Mode:Air-Cooled |

| Punching & Cutting | Mold Structure:3-Plate 4-Column

Process Method:Hydraulic Shearing/Punching After Forming Disassembly Mode:Quick-Change Structure Mold Material:DC53 |

| Electric Control System | Core Function:Adjustable Length & Speed

PLC:Mitsubishi Frequency Converter:Sine/Chinese Famous Brand Encoder:Japanese Brand |

Flow Chart:

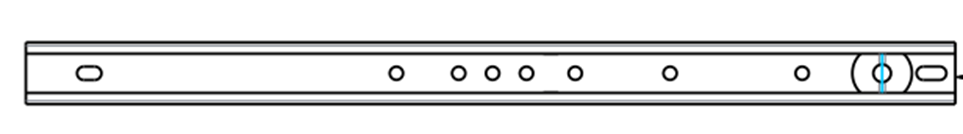

Profile Drawing: