DETAILS

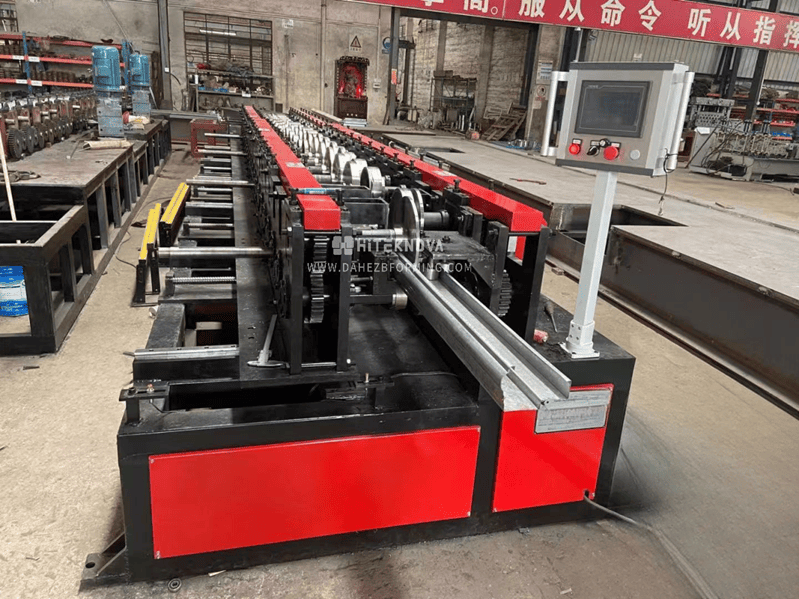

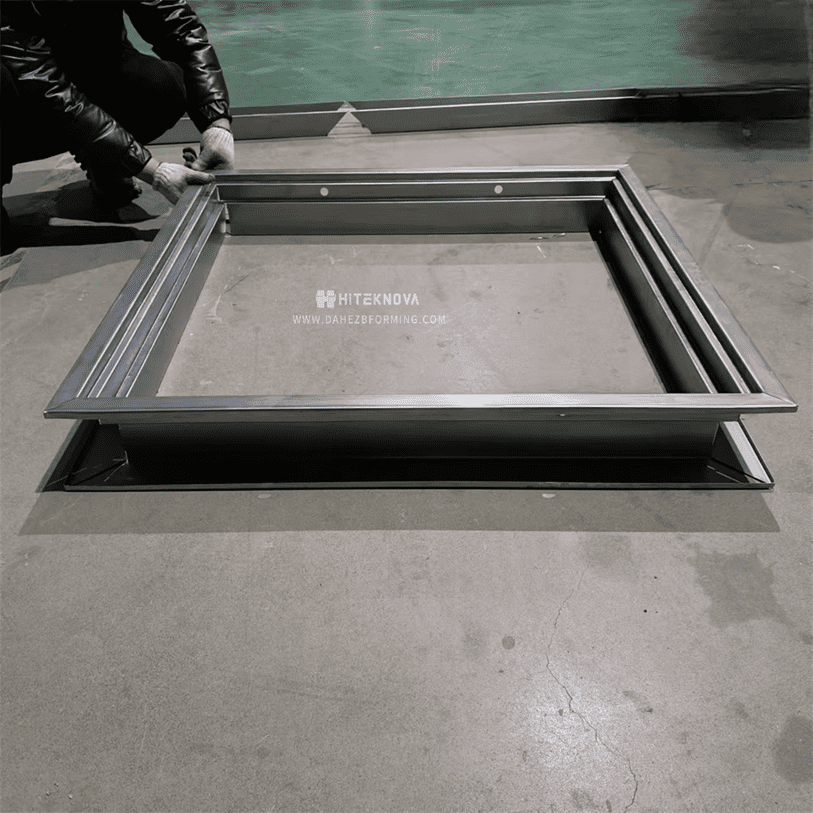

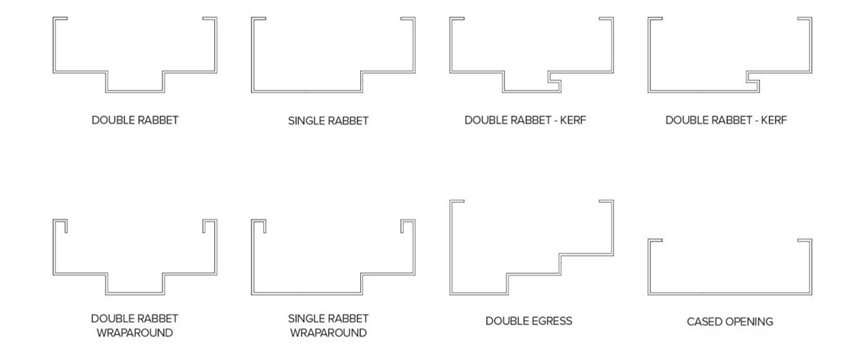

Our door frame roll forming machine produces door frame panels with specifications including 1.2–1.5mm thickness, 500–3000mm length and 90mm width, and supports customization as required. It is capable of processing various products such as transom frames, vertical frames, welded/assembled door frames.

Integrating automated forming, cutting and punching processes, the machine ensures stable product precision. It is ideal for manufacturing various metal door and window frames, including fire-resistant ones.

| Main Function | Producing door/window frames, with automated completion of the process: decoiling & leveling → pre-punching → roll forming → straightening → notch punching & cutting → unloading |

| Production Speed | Conveying Speed: 0-10m/min (adjustable); 2m vertical frames ≥3 pcs/min, 1m welded horizontal frames ≥4 pcs/min, 1m assembled horizontal frames ≥6 pcs/min |

| Raw Material Parameters | Material: Q235 cold-rolled steel plate, 304 stainless steel (coil); Material width: 210-300mm; Coil inner diameter: ф450-520mm, outer diameter: ф1200mm; Weight: 3000Kg |

| Key Components | Pressure wheels (Cr12MoV, HRC 58-62); Rollers (ф55mm, 40Cr); Dies / Punches / Cutters (Cr12MoV, service life: 300,000 cycles) |

| Control System | Touch screen + PLC programming, supporting independent program selection, servo-adjustable, with counting and digital display functions |

| Safety Configuration | Safety shields + interlock protection, non-exposed wiring, and equipped with a waste collection hopper |

Profile Drawings

Machine Video

Machine Picture

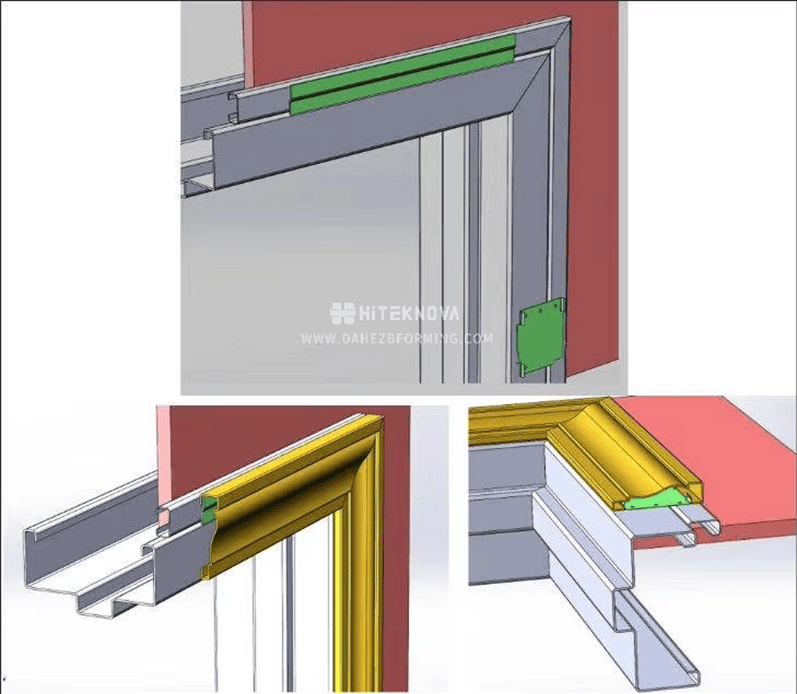

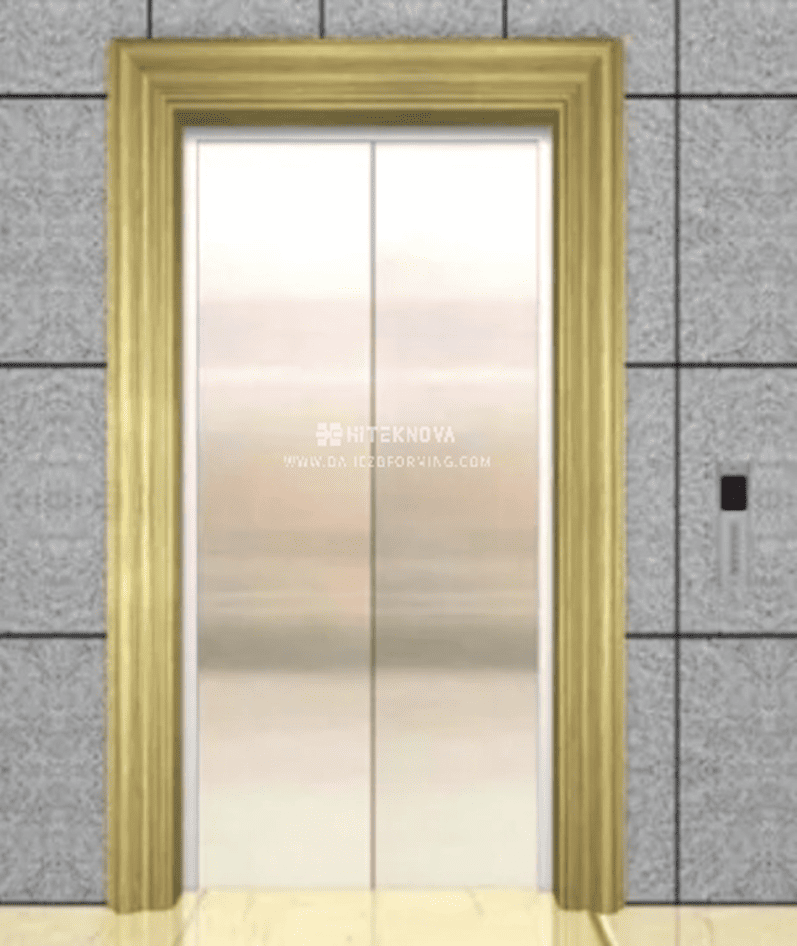

Application