One Machine for Six Profiles

Smart adaptation to multiple profile types with adjustable punching configurations.

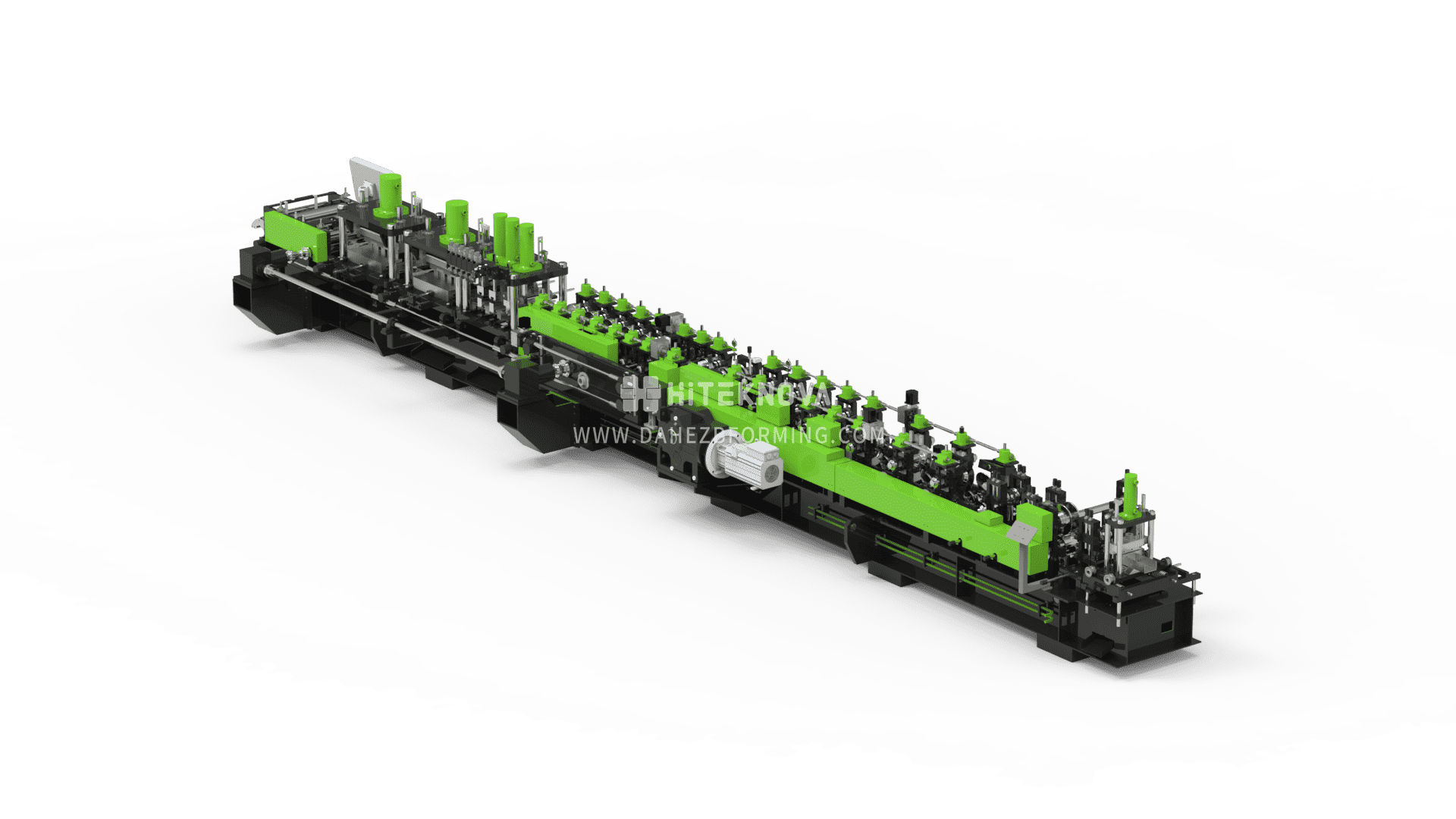

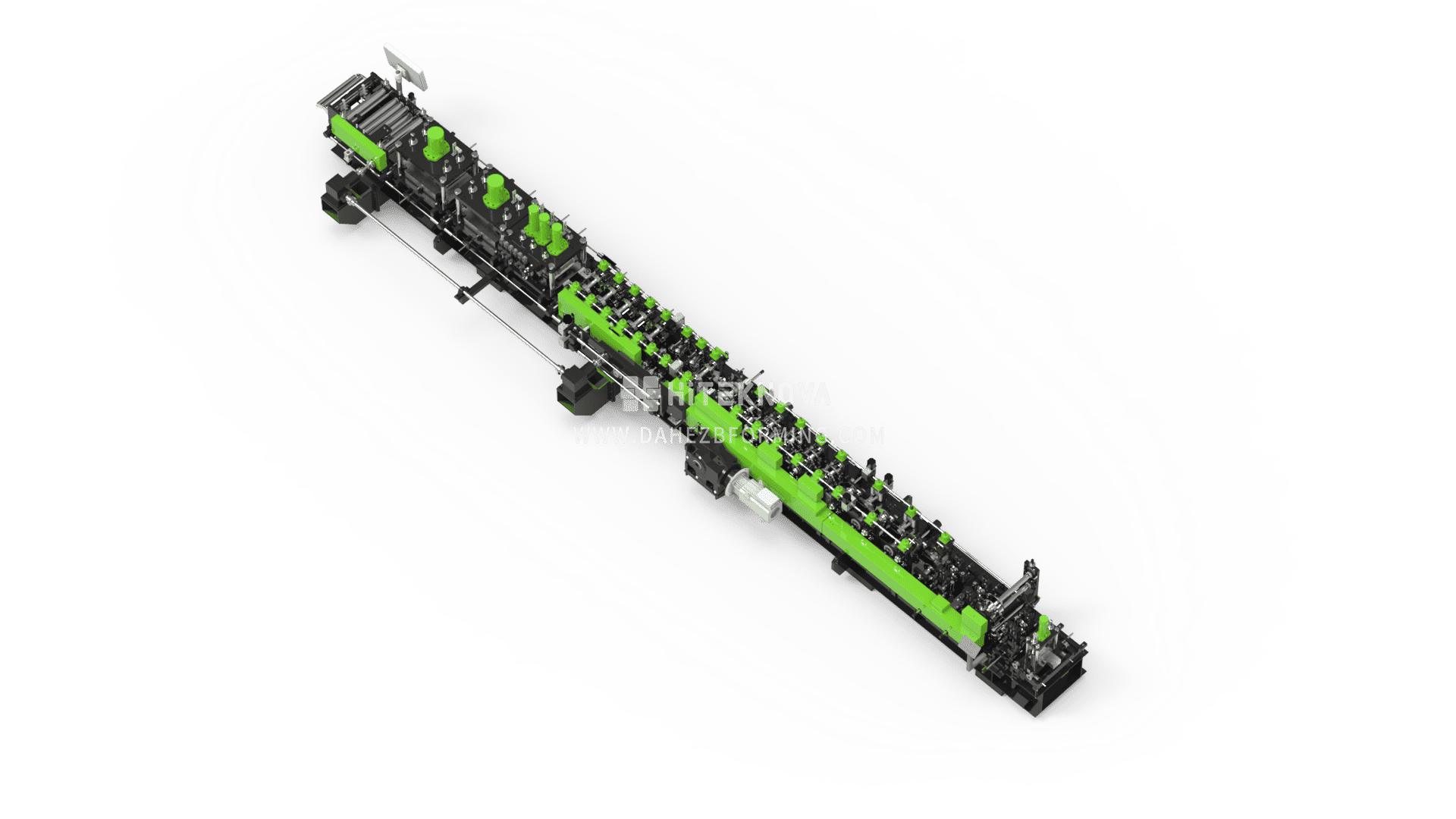

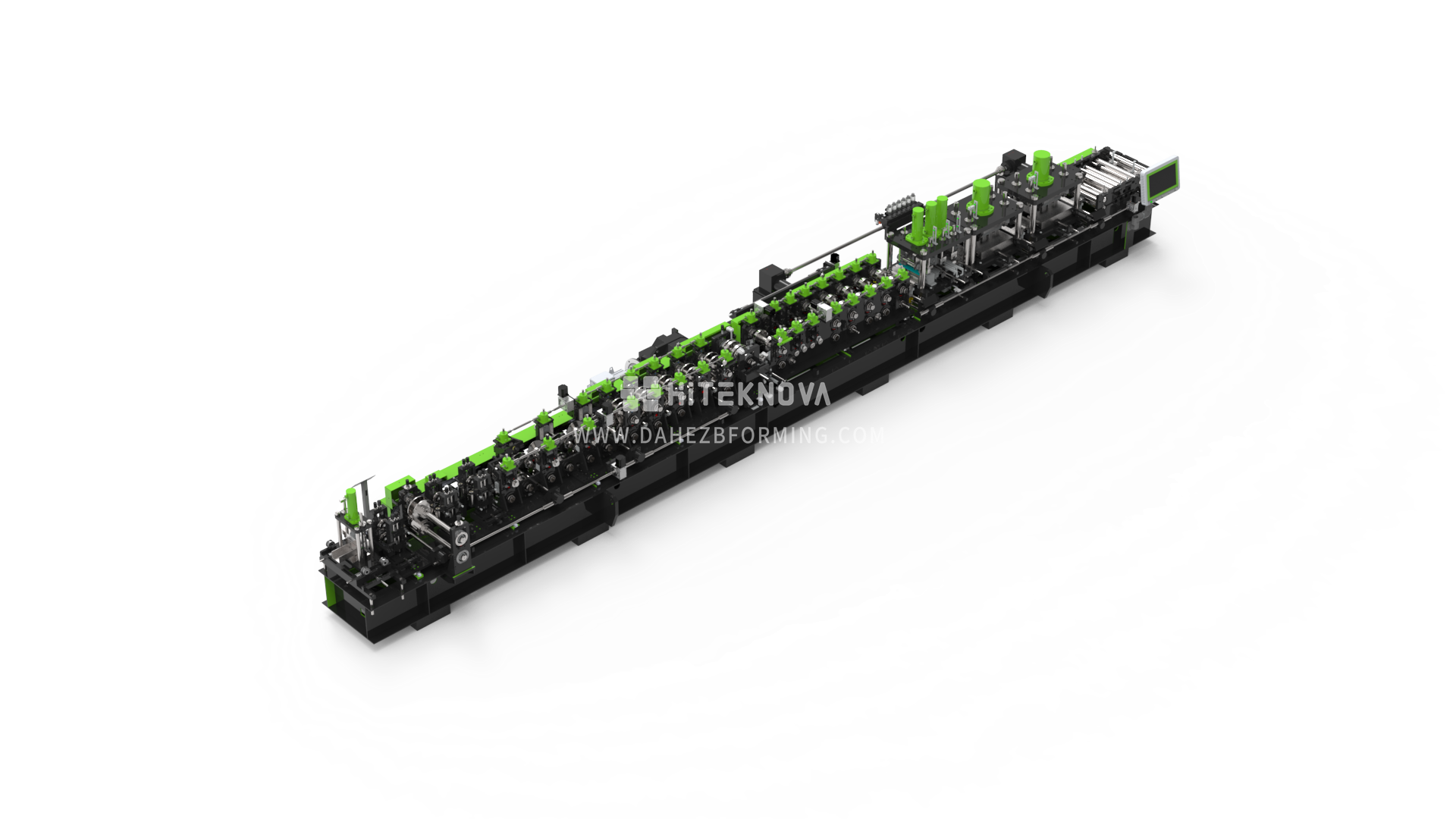

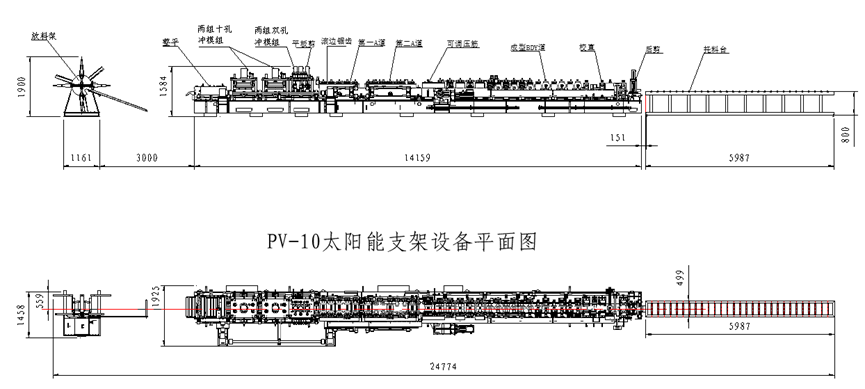

HITEKNOVA has developed the PV10 Solar Mounting Bracket Production Line, entering the photovoltaic industry with strong innovation capabilities.

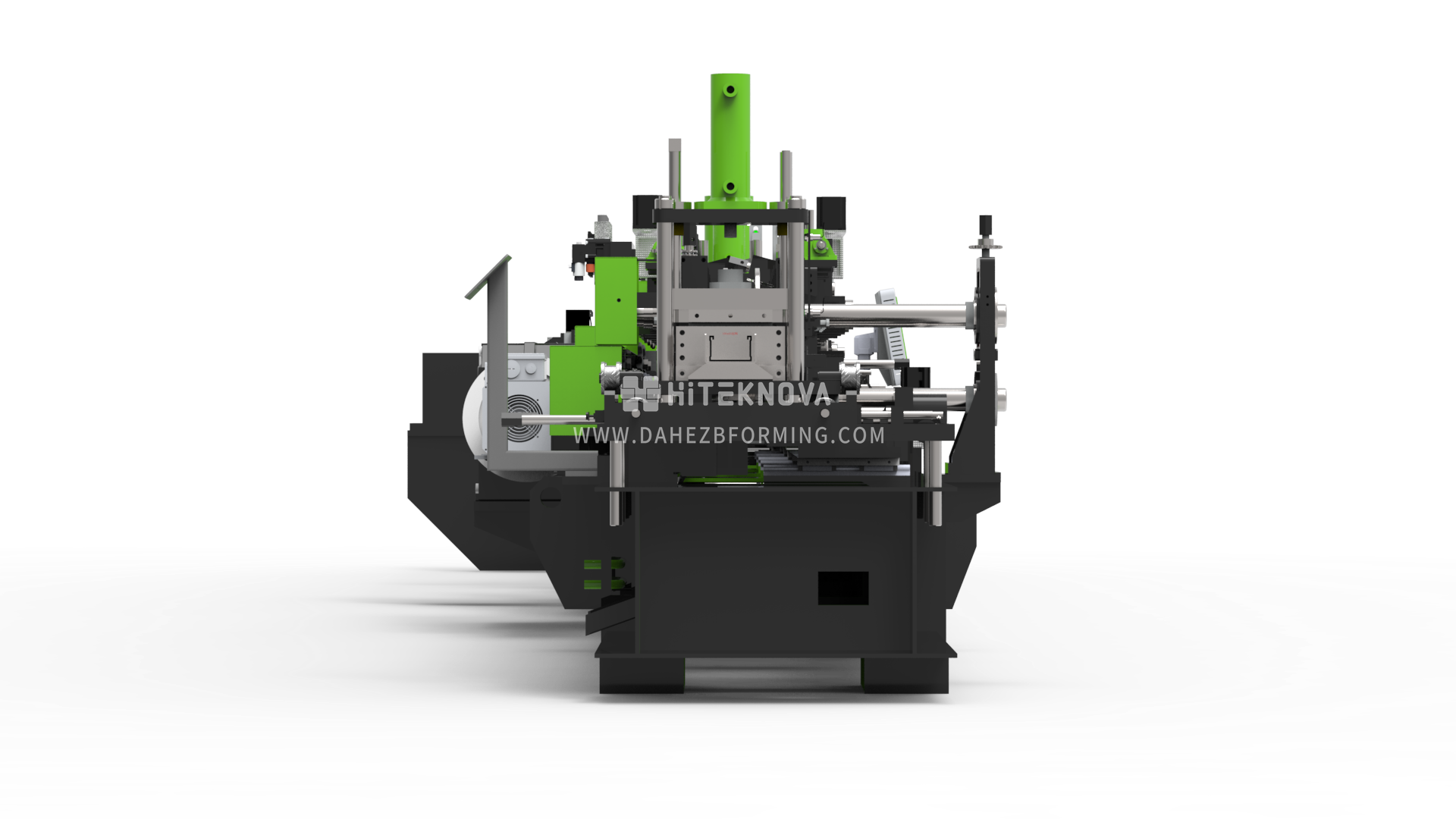

Equipped with HITEKNOVA’s proprietary AI software, the system features a front punching module with dual 10-station die sets and a stepless intelligent profile-change design.

It supports multi-profile production, adjustable punching patterns, and visualized operation, offering outstanding adaptability for various products and factory layouts.

Brief Technical Specification

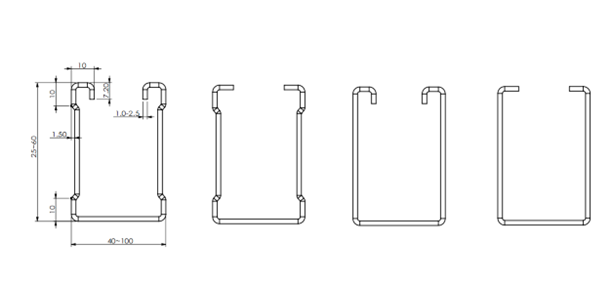

| Item | Details |

| Profile | Solar Panel Machine |

| Width | 40-100mm |

| Height | 25-60mm |

| Flange | 10mm |

| Lip | 7-20mm |

| Thickness | 1-2.5mm |

| Material Type | Hot-rolled strip steel or hot-dip galvanized strip steel |

| Yield Strength | ≤350MPA |

| Forming Speed | High speed: 35m/min |

| Drive Type | Chain Driving Type |

| Production Control System | PLC Control |

| Cutting System | Hydraulic Cutting |

| Forming Stations | 25 Stations |

| Main Motor | 30kw |

| Hydralic Motor | 30kw |

| Voltage | 380V/50HZ/3P |

| Equipment Dimension | 14500 *2000 *1600 |

Flow Chart:

Decoiler – Leveling device – Roll Forming System – Post-cutting – Product Support Table

Profile Drawing:

Machine Video

Machine Picture

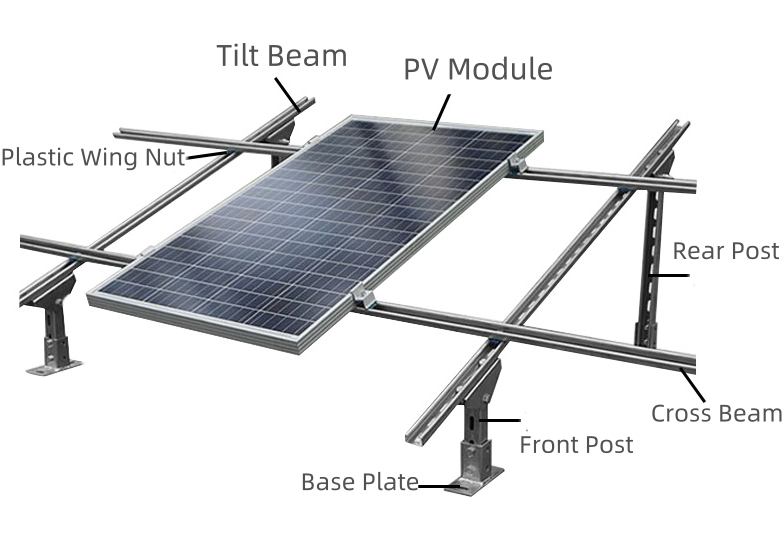

Application Scenario